Product Description

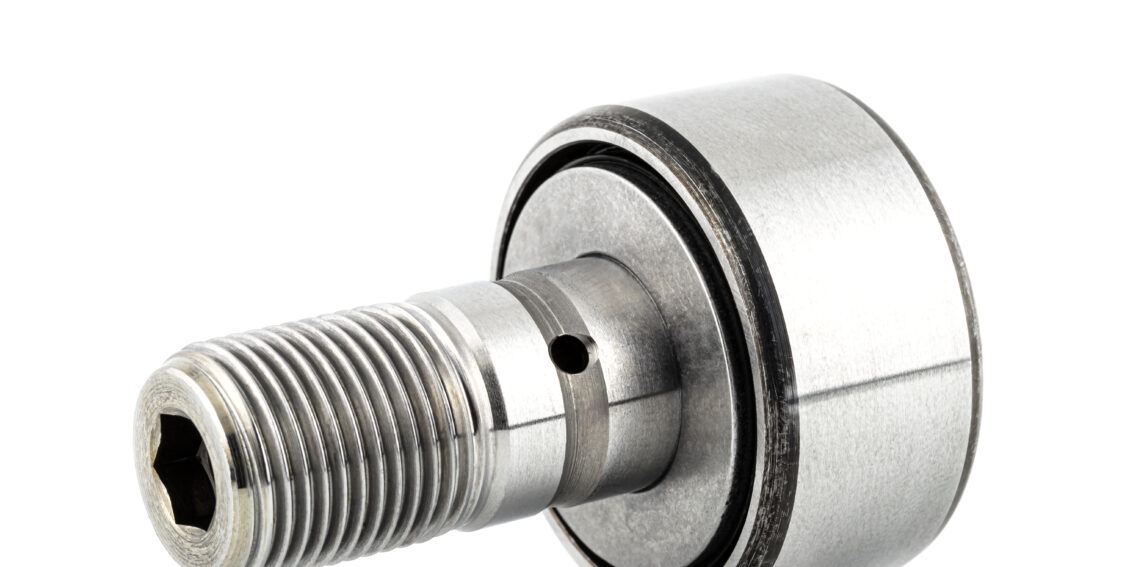

Double Row Ball Bearing Track Roller With Integral Stud

Double rows angular contact ball bearing track rollers with “V” groove profile on outer ring and integral stud. Factory greased with high-performance lithium soap grease. Available with concentric and eccentric designs.

Design RV…C is without concentric stud

Design RV..E is with eccentric stud

Track rollers with integral studs are supplied with split washer and nut.

The unit contamination protection is provided by side shields ZZ.

I have all the models you need, these are just some of them, please contact us now

| Part No | dw | D | C | L | e | Cr | C0r | Weight | NIKO |

| mm | mm | mm | mm | mm | N | N | kg | ||

| RV22-10C | 10 | 22 | 11 | 26 | 2,450 | 1,620 | 0.571 | RV22C | |

| RV22-10E | 10 | 22 | 11 | 26 | 1.5 | 2,450 | 1,620 | 0.571 | RV22E |

| RV30-10C | 10 | 30 | 14 | 33 | 4,490 | 2,700 | 0.069 | RV30C | |

| RV30-10E | 10 | 30 | 14 | 33 | 1.5 | 4,490 | 2,700 | 0.069 | RV30E |

| RV38-10C | 10 | 38 | 17 | 42 | 7,290 | 4,550 | 0.145 | RV38C | |

| RV38-10E | 10 | 38 | 17 | 42 | 2 | 7,290 | 4,550 | 0.145 | RV38E |

| RV41-20C | 20 | 41 | 20 | 47 | 8,180 | 5,100 | 0.190 | RV41C | |

| RV41-20E | 20 | 41 | 20 | 47 | 2 | 8,180 | 5,100 | 0.190 | RV41E |

| RV58-20C | 20 | 58 | 25 | 59 | 16,580 | 9,200 | 0.460 | RV58C | |

| RV58-20E | 20 | 58 | 25 | 59 | 2.5 | 16,580 | 9,200 | 0.460 | RV58E |

• Industrial machinery: printing machinery, paper machinery, automation machinery, textile machinery, vending machines, woodworking machinery, packaging machinery

• Electronic equipment: mechanical arm, measuring equipment, X-X platform, medical equipment, factory automation equipment

• Rotation machinery: metal heat treatment designed nuclear reactor, brakes, etc

• Aerospace industries: aircraft flaps brakes, seat brakes, missiles, airport apparatus and other equipment

• Other: radio antenna brakes, door and window control, medical bed control, parking facilities, machine tool doors, laboratory automation, etc.

1.FREE SAMPLES:

contact us by email or trade manager, we will send the free sampls according to your request.

2. World Class Bearing:We provide our customers with all type of indigenous bearing with world class quality.

3. OEM or Non Stand Bearings: Any requirement for Non standard bearings is Easily Fulfilled by us due to

its vast knowledge and links in the industry.

4. Genuine products With Excellent Quality: Company has always proved the

100% quality products it provides with genuine intent.

5.After Sales Service and technical Assistance: Company provides after sales service and technical assistance

as per the customers requirement and needs.

6. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

7. Cost Saving: We provide long-life, shock-resistant and high reliability bearings with

excellent quality and better performance. Resulting in increased cost saving.

8.Attending customer queries promptly: We believe that if customer are satisfied

then it proves our worth well. Customers are always given quick support.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Radial Bearing |

| Customization: |

Available

| Customized Request |

|---|

How does proper installation and alignment impact the performance and longevity of track bearings?

Proper installation and alignment play a critical role in the performance and longevity of track bearings. Correct installation ensures that the bearings are positioned and secured accurately, while proper alignment ensures that the load is distributed evenly and the bearings operate smoothly. Here’s an explanation of how proper installation and alignment impact the performance and longevity of track bearings:

Installation Impact:

- Load Distribution: Proper installation ensures that the track bearings are aligned and positioned correctly, allowing for even load distribution. When bearings are installed incorrectly, the load may be unevenly distributed, leading to excessive wear on certain parts of the bearings and reduced overall performance.

- Stability and Rigidity: Accurate installation provides stability and rigidity to the track bearings. Properly secured bearings minimize the risk of movement or vibration during operation, which can cause additional stress, premature wear, and potential damage to the bearings and surrounding components.

- Reduction of Misalignment: Correct installation minimizes the chances of misalignment between the track bearings and the track or guide rails. Misalignment can lead to uneven loading, increased friction, and accelerated wear and tear on the bearings. Proper alignment reduces these issues, ensuring smooth and efficient operation.

- Prevention of Contamination: During installation, it is important to take precautions to prevent contamination of the track bearings. Proper handling techniques, cleanliness, and the use of appropriate tools or protective measures help avoid introducing dirt, dust, or debris that can compromise the bearing’s performance and longevity.

Alignment Impact:

- Reduced Friction and Wear: Proper alignment of track bearings helps minimize friction and wear. When bearings are misaligned, excessive forces and irregular motion can occur, leading to increased friction and accelerated wear. Proper alignment ensures that the bearings operate within their intended design parameters, reducing friction and promoting longevity.

- Optimal Load Distribution: Correct alignment ensures that the load is distributed evenly across the track bearings. This prevents excessive stress on specific areas of the bearings, reducing the risk of premature failure and extending their service life. Optimal load distribution also contributes to smoother operation and improved overall performance.

- Minimized Noise and Vibration: Proper alignment helps minimize noise and vibration during operation. Misaligned track bearings can result in irregular motion, leading to unwanted noise and vibration that can affect the performance, comfort, and efficiency of the machinery or equipment. Proper alignment promotes smoother and quieter operation.

- Improved Efficiency: When track bearings are correctly aligned, the machinery or equipment experiences reduced resistance and improved efficiency. Misalignment can result in energy losses, increased power consumption, and decreased overall efficiency. Proper alignment ensures optimal power transfer and minimizes energy wastage.

It is important to follow the manufacturer’s guidelines and recommendations for the specific track bearings being installed. Proper installation techniques, including accurate positioning, secure fastening, and appropriate alignment, contribute to the optimal performance, reliability, and longevity of track bearings in various applications.

Can track bearings withstand harsh environments or exposure to contaminants?

Track bearings are designed to operate in a wide range of environments, including harsh conditions and exposure to contaminants. However, the ability of track bearings to withstand such environments depends on their specific design, materials, and protective measures. Here’s a detailed explanation:

Many track bearings are engineered with features that enhance their resistance to harsh environments and contaminants. These features may include:

- Sealing and Shielding: Some track bearings are equipped with seals or shields that provide a physical barrier against contaminants such as dirt, dust, water, and debris. These seals or shields help prevent the entry of contaminants into the bearing’s internal components, reducing the risk of damage and premature wear.

- Corrosion Resistance: Track bearings intended for use in corrosive environments are often constructed from materials that offer high corrosion resistance. Stainless steel, for example, is commonly used due to its ability to withstand exposure to moisture, chemicals, and other corrosive substances.

- Specialized Coatings: Some track bearings may feature specialized coatings or surface treatments that provide additional protection against contaminants and harsh conditions. These coatings can enhance the bearing’s resistance to corrosion, abrasion, and chemical exposure.

- High-Temperature Capability: Certain track bearings are designed to withstand high-temperature environments. They are typically constructed using heat-resistant materials and lubricants that can maintain their structural integrity and performance even under extreme heat.

- Environmental Sealing: In applications where track bearings are exposed to extreme conditions, such as underwater or in highly dusty environments, special environmental sealing measures may be employed. These measures can include the use of advanced sealing technologies or the encapsulation of the bearings within protective housings.

While track bearings are designed to withstand harsh environments and exposure to contaminants, it is important to note that their performance and longevity can still be affected over time. Regular maintenance, including cleaning, inspection, and lubrication, is crucial to ensure proper functioning and to mitigate the impact of contaminants on the bearings.

It is recommended to consult the manufacturer’s specifications and guidelines for the track bearings being used in a specific application. Manufacturers often provide information on the environmental ratings and limits of their bearings, helping users determine the suitability of the bearings for particular harsh environments or exposure to contaminants.

By selecting track bearings with appropriate features, materials, and protection, and by implementing proper maintenance practices, it is possible to enhance the bearings’ ability to withstand harsh environments and exposure to contaminants, thereby maximizing their performance and longevity.

How do track bearings compare to other types of bearings like ball bearings or roller bearings?

Track bearings, ball bearings, and roller bearings are all types of rolling bearings used in various applications. Let’s compare track bearings to ball bearings and roller bearings to understand their similarities and differences:

- Design and Construction: Track bearings, ball bearings, and roller bearings have different designs and constructions. Track bearings, also known as track rollers or track follower bearings, are designed specifically for guided linear or rotational motion along a track or guide rail. They feature an outer ring with a track surface, an inner ring, rolling elements (such as rollers or needles), and a cage. Ball bearings, on the other hand, have spherical rolling elements (balls) sandwiched between inner and outer rings. Roller bearings, as the name suggests, have cylindrical or tapered rolling elements (rollers) between inner and outer rings.

- Motion and Load Handling: Track bearings are primarily used for guided motion in track-based systems, while ball bearings and roller bearings are used for general rotational or linear motion. Track bearings are designed to support both radial and axial loads and provide smooth and controlled motion along the track. Ball bearings and roller bearings are also capable of supporting radial and axial loads but are typically used in applications where the motion is not constrained to a specific track or guide rail. Roller bearings, with their larger contact area and higher load-carrying capacity, are often preferred for applications with higher loads.

- Applications: Track bearings are commonly used in applications such as material handling systems, conveyors, cam mechanisms, automated machinery, construction equipment, and agricultural machinery, where guided motion along a track or rail is required. Ball bearings and roller bearings find applications in a wide range of industries and systems, including electric motors, pumps, automotive applications, industrial machinery, and appliances.

- Friction and Efficiency: Track bearings, ball bearings, and roller bearings all aim to minimize friction and ensure efficient operation. However, due to their different designs and contact surfaces, they exhibit varying levels of friction. Ball bearings typically have lower friction due to point contact between the balls and the raceways. Roller bearings, especially tapered roller bearings, distribute the load over a larger contact area, resulting in slightly higher friction compared to ball bearings. Track bearings, with their track interface, may have slightly higher friction compared to ball bearings or roller bearings due to the rolling elements’ contact with the track surface.

- Installation and Maintenance: Track bearings, ball bearings, and roller bearings require proper installation and maintenance for optimal performance and longevity. However, track bearings may require additional attention during installation as they need to be properly aligned with the track or guide rail. Regular lubrication and periodic inspection are essential for all types of bearings to ensure smooth operation and prevent premature failure.

In summary, track bearings, ball bearings, and roller bearings have distinct designs and applications. Track bearings are specialized for guided motion along a track or rail, while ball bearings and roller bearings are more versatile and used in a wide range of rotational or linear motion applications. Each type of bearing has its advantages and considerations in terms of load handling, friction, efficiency, and installation requirements. Selecting the appropriate bearing type depends on the specific application requirements, load conditions, motion characteristics, and environmental factors.

editor by CX 2024-04-26