Product Description

NNTR 110X260X115 2ZL yoke type track roller bearing NNTR105710/NNTR110260/NNTR125710/NNTR13571/NNTR140340/NNTR150360

NNTR50130/NNTR55140/NNTR60150/NNTR65160/NNTR70180/NNTR85710/NNTR85710//NNTR95710/NNTR105710/NNTR110260/NNTR125710/NNTR13571/NNTR140340/NNTR150360

NUTR15(X) NUTR1542(X) NUTR17(X) NUTR1747(X) NUTR20(X) NUTR2052(X) NUTR25(X) NUTR2562(X) NUTR30(X) NUTR3072(X) NUTR35(X) NUTR3580(X) NUTR40(X) NUTR4090(X) NUTR45(X) NUTR45100(X) NUTR50(X)NUTR50110(X) NUTR15/NUTR17/NUTR20/NUTR25/NUTR30/NUTR35/NUTR40/NUTR45/NUTR50/NUTR1542/NUTR1741/NUTR2562/NUTR3072/NUTR3580/NUTR4090/NUTR45100/NUTR50110/NUTR40X/NUTR1538/NUTR1542/NUTR2052/NUTR2562/NUTR4085/NUTR4090/NATV5,NATV6,NATV8,NATV10,NATV12,NATV15,NATV17,NATV20,NATV25,NATV30,NATV35,NATV40,NATV45,NATV50,NATV5-PP,NATV6-PP,NATV8-PP,NATV10-PP,NATV12-PP,NATV15-PP,NATV17PP,NATV20PP,NATV25PP,NATV30PP,NATV40PP,NATV45PP,NATV50PP NATR5,NATR6,NATR8,NATR10,NATR12,NATR15,NATR17,NATR20,NATR25,NATR30,NATR35,NATR40,NATR45,NATR50,NATR5-PP,NATR6-PP,NATR8-PP,NATR10-PP,NATR12-PP,NATR15-PP,NATR17-PP,NATR20-PP,NATR25-PP,NATR30-PP,NATR35-PP,NATR40-PP,NATR45-PP,NATR50-PP NA22,6-2RS,NA22,8-2RS,NA2200-2RS,NS2201-2RS,NA2202-2RS,NA2203-2RS,NA2204-2RS,NA2205-2RS,NA2206-2RS,NA2207-2RS,NA2208-2RS,NA2209-2RS,NA2210-2RS RNA22/6-2RS/RNA22/8-2RS/RNA2200-2RS/RNA2201-2RS/RNA2202-2RS/RNA2203-2RS/RNA2204-2RS/RNA22082RS/STO6/STO8/STO10/STO12/STO15/STO17/STO20/STO25/STO25X/STO30/STO35/STO40/STO45/STO50

| NUTR Series | ||||

| Item | Weight(g) | d(mm) | D(mm) | B(mm) |

| NUTR15 | 99 | 15 | 35 | 19 |

| NUTR1542 | 158 | 15 | 42 | 19 |

| NUTR17 | 147 | 17 | 40 | 21 |

| NUTR1747 | 220 | 17 | 47 | 21 |

| NUTR20 | 245 | 20 | 47 | 25 |

| NUTR2052 | 321 | 20 | 52 | 25 |

| NUTR25 | 281 | 25 | 52 | 25 |

| NUTR2562 | 450 | 25 | 62 | 25 |

| NUTR30 | 465 | 30 | 62 | 29 |

| NUTR3072 | 697 | 30 | 72 | 29 |

| NUTR35 | 630 | 35 | 72 | 29 |

| NUTR3580 | 836 | 35 | 80 | 29 |

| NUTR40 | 816 | 40 | 80 | 32 |

| NUTR4090 | 1129 | 40 | 90 | 32 |

| NUTR45 | 883 | 45 | 85 | 32 |

| NUTR45100 | 1396 | 45 | 100 | 32 |

| NUTR50 | 950 | 50 | 90 | 32 |

| NUTR50110 | 1690 | 50 | 110 | 32 |

| NATR Series | ||||

| Item | Weight(g) | d(mm) | D(mm) | B(mm) |

| NATR5 | 14 | 5 | 16 | 12 |

| NATR6 | 20 | 6 | 19 | 12 |

| NATR8 | 41 | 8 | 24 | 15 |

| NATR10 | 64 | 10 | 30 | 15 |

| NATR12 | 71 | 12 | 32 | 15 |

| NATR15 | 101 | 15 | 35 | 19 |

| NATR17 | 144 | 17 | 40 | 21 |

| NATR20 | 246 | 20 | 47 | 25 |

| NATR25 | 275 | 25 | 52 | 25 |

| NATR30 | 470 | 30 | 62 | 29 |

| NATR..PP Series | ||||

| Item | Weight(g) | d(mm) | D(mm) | B(mm) |

| NATR5 PP | 14 | 5 | 16 | 12 |

| NATR6 PP | 19 | 6 | 19 | 12 |

| NATR8 PP | 38 | 8 | 24 | 15 |

| NATR10 PP | 64 | 10 | 30 | 15 |

| NATR12 PP | 66 | 12 | 32 | 15 |

| NATR15 PP | 95 | 15 | 35 | 19 |

| NATR17 PP | 139 | 17 | 40 | 21 |

| NATR20 PP | 236 | 20 | 47 | 25 |

| NATR25 PP | 271 | 25 | 52 | 25 |

| NATR30 PP | 444 | 30 | 62 | 29 |

| NATR35 PP | 547 | 35 | 72 | 29 |

| NATR40 PP | 795 | 40 | 80 | 32 |

| NATR50 PP | 867 | 50 | 90 | 32 |

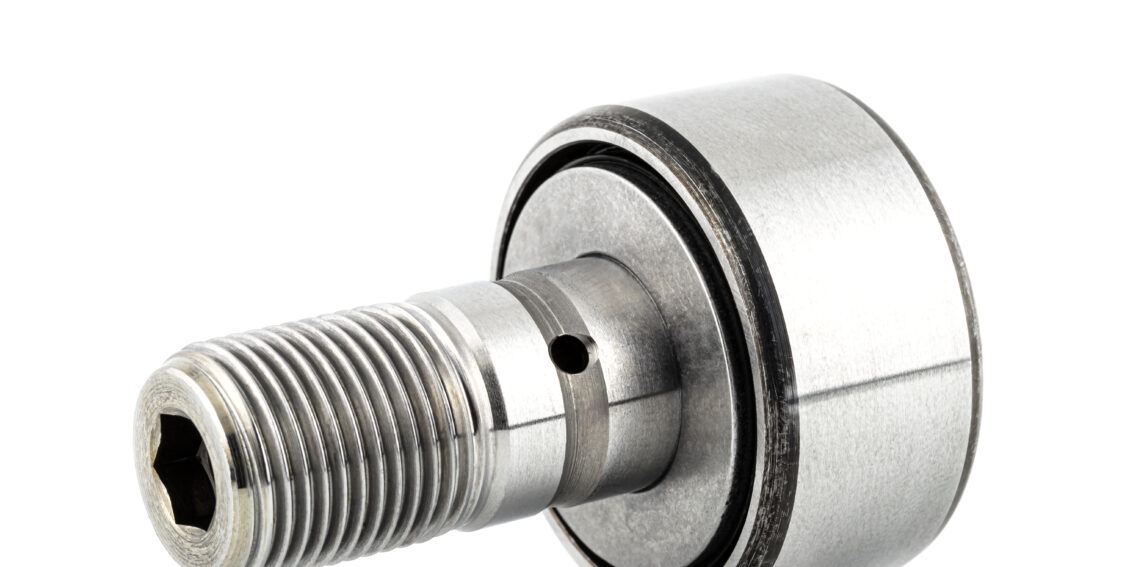

The YOKE type track roller bearing NUTR2052 are manufactured according to the Unified Parameters of rolling bearings. This series can be supplied both with a retaining cap which can therefore be relubricated and a sealed types.

These YOKE type track roller bearing NUTR2052 are greased with grade “3” lithium base grease. For special using, such as at high temperatures, please consult us.

The uses is recommended in all applications where heavy and sudden loads are foreseen.

| Precision | P0,p6,p5 |

| Tolerance grade | GB/T307.1-205 |

| Greese/Oil | As you requirement, such as SRL ,PS2, Alvania R12 and so on |

| Quality standard | ISO 9001:2008 standard |

| features | long life with high quality |

| low noise with strict controlling of bearing quality | |

| high load by the advanced high-technical design | |

| competitive price | |

| OEM service to meet your requirements | |

| international standard .first- class in china | |

| manufacture process | We have complete process for the production and quality assurance to make sure our products can meet your requirement. 1.Assembly 2.Windage test 3.Cleaning 4.Rotary test 5.Greasing and gland 6.Noise inspection 7.Appearance inspection 8.Rust prevention 9.Product packaging |

| sample | available |

| MOQ | ONE |

| Delivery Date | As soon as possible for your requirement |

| Payment Term | A: 30% T/T in Advance, 70% T/T Against Copy Of B/L |

| 30% T/T in adwance, 70% T/T before delivery | |

| B: 100% L/C At Sight | |

| C: 100% Western Union or Paypal in advance.(specially for air shipment or small amount) | |

| Brand | ZHH or OEM,etc. |

| Packaging Details: | 1.Neutral packing(neutral plastic bag+neutral tan box+neutral carton+Plywood pallets 2.Color box packing(plastic bag+color box+carton)+Plywood pallets 3.As the clients’ requirement |

| shipping | 1) Less than 45 KGS, we will send by express. ( Door to Door, Convenient ) 2) Between 45 – 200 KGS, we will send by air transport. ( Fastest and safest, ) 3) More than 200 KGS, we will send by sea. ( Cheapest ) |

| port of shippment by sea | ZheJiang HangZhou HangZhou |

WHY CHOOSE US

1 . QUALITY CONTROL :

More than 10 years of industry experience,and the factory equipment is from JAPAN AND GERMAN,100% test the quality before delivery.

2 . SUPPORT :

24-hour response in english on line and provide technical support.

3 . RICH STOCK :

Huge stock goods ensure you Very Short Delivery Time(Generally 1- 3 days after payment for stocks.

4 . GOOD AFTER SALES SERIVICE :

(One year quality warranty, money can be deducted or refund if any quality problem).

5 . PROFESSIONAL :

Well-trained & experienced staff are to answer all your inquiries in English of course.

6 . CONFIDENTIAL :

Your business relationship with us will be confidential to any third party.

7 . GOOD MATERAILS :

We only use the best steel on the market.

8 . POWERFUL PARTNER :

Our Bearings are mated with many well-known enterpriss, such as Japan Mabuchimotor, Germany BBS, America Leeson globally and domestic. Our Bearings are exported to more than 120 countries and regions including US, Italy, Germany, Egypt an the Middle East.

9 . TESTING :

100% test of the quality and packing will be done before delivery.

10. OVERSEAS EXHIBITIONS :

We have more than 5 chances to attend exhibitions overseas , which means that we have the ability of providing professional suggestions and best service for our clients;

OUR PROMISES

Product quality standards are guaranteed. Our products have got ISO 9001 & CE international quality management system. They all produced with best advanced technology.We are proactive and we offer only products complying with top standards of quality and warranty. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel, Chrome Steel, Gcr15 |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Radial Bearing |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does proper installation and alignment impact the performance and longevity of track bearings?

Proper installation and alignment play a critical role in the performance and longevity of track bearings. Correct installation ensures that the bearings are positioned and secured accurately, while proper alignment ensures that the load is distributed evenly and the bearings operate smoothly. Here’s an explanation of how proper installation and alignment impact the performance and longevity of track bearings:

Installation Impact:

- Load Distribution: Proper installation ensures that the track bearings are aligned and positioned correctly, allowing for even load distribution. When bearings are installed incorrectly, the load may be unevenly distributed, leading to excessive wear on certain parts of the bearings and reduced overall performance.

- Stability and Rigidity: Accurate installation provides stability and rigidity to the track bearings. Properly secured bearings minimize the risk of movement or vibration during operation, which can cause additional stress, premature wear, and potential damage to the bearings and surrounding components.

- Reduction of Misalignment: Correct installation minimizes the chances of misalignment between the track bearings and the track or guide rails. Misalignment can lead to uneven loading, increased friction, and accelerated wear and tear on the bearings. Proper alignment reduces these issues, ensuring smooth and efficient operation.

- Prevention of Contamination: During installation, it is important to take precautions to prevent contamination of the track bearings. Proper handling techniques, cleanliness, and the use of appropriate tools or protective measures help avoid introducing dirt, dust, or debris that can compromise the bearing’s performance and longevity.

Alignment Impact:

- Reduced Friction and Wear: Proper alignment of track bearings helps minimize friction and wear. When bearings are misaligned, excessive forces and irregular motion can occur, leading to increased friction and accelerated wear. Proper alignment ensures that the bearings operate within their intended design parameters, reducing friction and promoting longevity.

- Optimal Load Distribution: Correct alignment ensures that the load is distributed evenly across the track bearings. This prevents excessive stress on specific areas of the bearings, reducing the risk of premature failure and extending their service life. Optimal load distribution also contributes to smoother operation and improved overall performance.

- Minimized Noise and Vibration: Proper alignment helps minimize noise and vibration during operation. Misaligned track bearings can result in irregular motion, leading to unwanted noise and vibration that can affect the performance, comfort, and efficiency of the machinery or equipment. Proper alignment promotes smoother and quieter operation.

- Improved Efficiency: When track bearings are correctly aligned, the machinery or equipment experiences reduced resistance and improved efficiency. Misalignment can result in energy losses, increased power consumption, and decreased overall efficiency. Proper alignment ensures optimal power transfer and minimizes energy wastage.

It is important to follow the manufacturer’s guidelines and recommendations for the specific track bearings being installed. Proper installation techniques, including accurate positioning, secure fastening, and appropriate alignment, contribute to the optimal performance, reliability, and longevity of track bearings in various applications.

How do track bearings enhance the overall efficiency and functionality of linear motion systems?

Track bearings play a crucial role in enhancing the overall efficiency and functionality of linear motion systems. They offer several benefits that contribute to improved performance, increased reliability, and enhanced functionality. Here’s a detailed explanation:

- Reduced Friction: Track bearings are designed to minimize friction between moving components, allowing for smoother and more efficient linear motion. By reducing friction, they help to optimize the efficiency of the system, reducing energy consumption and minimizing wear on the components.

- Precision and Stability: Track bearings provide precise guidance and stability to the linear motion system. They ensure accurate and repeatable motion along the intended path, allowing for precise positioning and control. This is particularly important in applications that require high accuracy, such as CNC machines, robotics, and automated assembly lines.

- Load Distribution: Track bearings distribute the load evenly along their length, allowing for efficient load transfer and reducing the concentration of forces on specific components. This helps to prevent excessive wear, deformation, and premature failure of the system, improving overall reliability and longevity.

- Handling Heavy Loads: Track bearings are specifically designed to handle heavy loads in linear motion systems. They offer high load capacities and robust construction, enabling them to support and move heavy objects with ease. This capability is essential in industries such as material handling, construction, and transportation.

- Smooth and Quiet Operation: Track bearings are engineered to provide smooth and quiet operation, minimizing noise and vibrations in the linear motion system. This is especially important in applications where noise reduction and comfort are critical, such as in medical equipment, office automation, and consumer electronics.

- Versatility and Adaptability: Track bearings come in various designs, sizes, and configurations to accommodate different linear motion system requirements. They can be easily integrated into existing systems or customized to fit specific applications. This versatility allows for greater flexibility and adaptability in designing and implementing linear motion solutions.

- Maintenance and Serviceability: Track bearings are designed for ease of maintenance and serviceability. They often feature removable components, such as seals or shields, that allow for inspection, cleaning, and lubrication. This simplifies maintenance tasks and reduces downtime, contributing to improved overall system efficiency and uptime.

By incorporating track bearings into linear motion systems, industries can benefit from increased efficiency, improved performance, and enhanced functionality. Whether it’s achieving precise positioning, handling heavy loads, reducing friction, or ensuring smooth operation, track bearings play a vital role in optimizing the overall efficiency and functionality of linear motion systems.

What are the components of a track bearing assembly and their functions?

A track bearing assembly consists of several components that work together to facilitate smooth and controlled motion along a track or guide rail. Let’s explore the components of a typical track bearing assembly and their functions:

- Outer Ring: The outer ring is the outermost component of a track bearing assembly. It provides structural support and houses the rolling elements. The outer ring is designed with a track or guide surface that interfaces with the track or rail, allowing the bearing to move along the desired path.

- Inner Ring: The inner ring is located inside the outer ring and provides a mounting surface for the bearing assembly. It may have a stud or shaft for attaching the bearing to the application. The inner ring helps in aligning and positioning the bearing assembly.

- Rolling Elements: The rolling elements are the components that enable smooth rolling motion between the inner and outer rings. In track bearings, the rolling elements are typically in the form of rollers or needles. They are designed to minimize friction and distribute the load evenly along the track surface.

- Cage: The cage, also known as a retainer, is a component that holds the rolling elements in position and maintains proper spacing between them. The cage prevents the rolling elements from contacting each other, reducing friction and wear. It also helps in guiding the rolling elements during operation.

- Seals or Shields: Track bearings often incorporate seals or shields to protect the internal components from contaminants such as dirt, dust, and moisture. Seals provide a physical barrier between the bearing and the external environment, while shields offer partial protection while allowing some lubrication to reach the rolling elements.

- Lubrication: Proper lubrication is crucial for the smooth operation and longevity of track bearings. Lubrication reduces friction, dissipates heat, and prevents wear between the rolling elements and raceways. Lubricants can be applied through grease fittings or oil ports, ensuring that the rolling elements roll smoothly along the track surface.

- Mounting Hardware: Depending on the specific design and application requirements, track bearing assemblies may include mounting hardware such as studs, bolts, or fasteners. These components are used to securely attach the bearing assembly to the application, ensuring proper alignment and stability.

By combining these components, a track bearing assembly provides reliable and controlled motion along a track or guide rail. The outer and inner rings, along with the rolling elements and cage, enable smooth rolling motion, while seals or shields protect the internal components from contaminants. Proper lubrication and mounting hardware ensure optimal performance and longevity of the track bearing assembly.

editor by CX 2024-05-08