Product Description

| Specifications of Bearing |

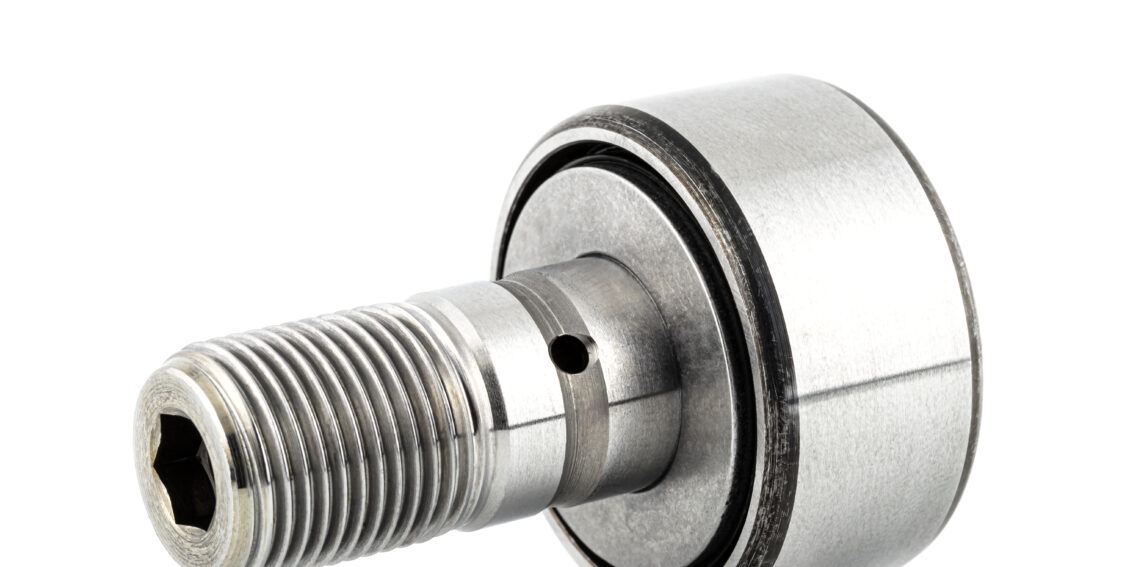

Track Roller Bearing

Product Description

| Basic Features of Track Roller Bearing | |

| Types | Stud type track roller bearing Yoke type track roller bearing |

| Series | RSTO… and STO… RNA22…2RS and NA22…RS NATR… and NATV… NUTR… KR… and KRE… KRV… and KRVE… NUKR… and NUKRE… NAST…ZZ PWTR…2RS KR52…NUUP PWKR…2RS |

| Material | Bearing Steel(GCr15, 100Cr6) SPCC St14 |

| Dimension | Metric and Inch |

| Dimension Range | 15mm~200mm(bore diameter) |

| MOQ | 1 |

| Delivery Time | 15-45 days |

| Sea Ports | ZheJiang HangZhou HangZhou |

Quick Details

Model Number: RNA4924, RNA4928, RNA4930

Bore Size: 10 – 150 mm

Bore Size: 135 mm

Outside Diameter: 165 mm

Number of Row: Double Row

Precision Rating: P0 P2 P4 P6

Seals Type: OPEN RS 2RS Z ZZ

Structure: Roller bearing

Sample: AcceptInternal

Clearance: C0 C1 C2 C3 needle roller bearing

Lubrication: Oil or grease

Material: GCr15, GCr15SiMn, G20Cr2Ni4A needle roller bearing

Cage: Stainless steel/brass/steel plate needle roller bearing

Service: OEM service, Design service, Buyer label service

Specifications

1. Material: GCr15, GCr15SiMn,

2. Certification: ISO9001: 2008

3. Supply competitive price

Stainless thrust bearing needle roller

Needle roller bearing features:

Needle roller bearing with pressed outer ring is made of high-quality thin sheet by fine stamping process. It has such characteristics as small structure space and large load capacity, and is suitably used for the place where the installing space is limited and case hole cannot be used as the rolling race. Further axial orientation is not necessary after pressing into the bearing seat hole. B series are inch-size drawn cup full complement needle roller bearings with open end.

Widely used in automobiles, motorcycles, power tools, textile machines, farm machines, printers, etc.

Needle roller bearing model series: NK, NKS, RNA49, RNA69, RNA49-RS, RNA49-2RS

Packaging & Delivery

Packaging Detail: Product Packing: Polybag+Box/Polybox or Wooden Box Outer Packing: Carton/Wooden Box + Pallet

Delivery Detail: 5-15days

| Showing of Bearing |

RSTO… and STO… series

| Bearing No. (without inner ring) |

Weight (g) |

Bearing No. (with inner ring) |

Weight (g) |

Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed (RPM) |

|||||||

| d | D | C | B | Fw | E | r | Cr | Cor | |||||

| RSTO 5TN | 8.5 | – | – | – | 16 | 7.8 | – | 7 | 10 | 0.3 | 2.55 | 2.55 | 16000 |

| RSTO 6TN | 12.5 | STO 6TN | 17 | 6 | 19 | 9.8 | 10 | 10 | 13 | 0.3 | 3.75 | 4.5 | 10000 |

| RSTO 8TN | 21 | STO 8TN | 26 | 8 | 24 | 9.8 | 10 | 12 | 15 | 0.3 | 4.2 | 5.5 | 8000 |

| RSTO 10 | 42 | STO 10 | 49 | 10 | 30 | 11.8 | 12 | 14 | 20 | 0.3 | 8.4 | 9.2 | 5500 |

| RSTO 12 | 49 | STO 12 | 57 | 12 | 32 | 11.8 | 12 | 16 | 22 | 0.3 | 8.9 | 10.1 | 4500 |

| RSTO 15 | 50 | STO 15 | 63 | 15 | 35 | 11.8 | 12 | 20 | 26 | 0.3 | 9.1 | 10.7 | 3300 |

| RSTO 17 | 88 | STO 17 | 107 | 17 | 40 | 15.8 | 16 | 22 | 29 | 0.3 | 14.3 | 17.7 | 2800 |

| RSTO 20 | 130 | STO 20 | 152 | 20 | 47 | 15.8 | 16 | 25 | 32 | 0.3 | 16.2 | 21.5 | 2400 |

| RSTO 25 | 150 | STO 25 | 177 | 25 | 52 | 15.8 | 16 | 30 | 37 | 0.3 | 16.5 | 22.9 | 1800 |

| RSTO 30 | 255 | STO 30 | 308 | 30 | 62 | 19.8 | 20 | 38 | 46 | 0.6 | 23.3 | 35 | 1300 |

| RSTO 35 | 375 | STO 35 | 441 | 35 | 72 | 19.8 | 20 | 42 | 50 | 0.6 | 25.5 | 40 | 1100 |

| RSTO 40 | 420 | STO 40 | 530 | 40 | 80 | 19.8 | 20 | 50 | 58 | 1 | 35 | 59.3 | 850 |

| RSTO 45 | 453 | STO 45 | 576 | 45 | 85 | 19.8 | 20 | 55 | 63 | 1 | 25.5 | 43 | 750 |

| RSTO 50 | 481 | STO 50 | 617 | 50 | 90 | 19.8 | 20 | 60 | 68 | 1 | 43.6 | 83.4 | 650 |

RNA22…2RS and NA22…2RS series

| Bearing No. (without inner ring) |

Weight (g) |

Bearing No. (with inner ring) |

Weight (g) |

Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed (RPM) |

||||||||

| d | D | C | B | Fw | D1 | r | r1 | Cr | Cor | |||||

| RNA22/6.2RS | – | NA22/6.2RS | – | 6 | 19 | 11.8 | 12 | 10 | 16 | 0.3 | 0.3 | 4.8 | 4.6 | — |

| RNA2200.2RS | 52 | NA2200.2RS | 60 | 10 | 30 | 13.8 | 14 | 14 | 20 | 0.6 | 0.3 | 8 | 8.5 | 5500 |

| RNA2201.2RS | 57 | NA2201.2RS | 67 | 12 | 32 | 13.8 | 14 | 16 | 22 | 0.6 | 0.3 | 7.5 | 9 | 4700 |

| RNA2202.2RS | 60 | NA2202.2RS | 75 | 15 | 35 | 13.8 | 14 | 20 | 26 | 0.6 | 0.3 | 8.2 | 9.6 | 3400 |

| RNA2203.2RS | 94 | NA2203.2RS | 112 | 17 | 40 | 15.8 | 16 | 22 | 28 | 1 | 0.3 | 9.7 | 10.8 | 3000 |

| RNA2204.2RS | 152 | NA2204.2RS | 177 | 20 | 47 | 17.8 | 18 | 25 | 33 | 1 | 0.3 | 15.2 | 18.3 | 2300 |

| RNA2205.2RS | 179 | NA2205.2RS | 209 | 25 | 52 | 17.8 | 18 | 30 | 38 | 1 | 0.3 | 15.7 | 20 | 1800 |

| RNA2206.2RS | 284 | NA2206.2RS | 324 | 30 | 62 | 19.8 | 20 | 35 | 43 | 1 | 0.6 | 18.4 | 25.5 | 1400 |

| RNA2207.2RS | 432 | NA2207.2RS | 505 | 35 | 72 | 22.7 | 23 | 42 | 50 | 1.1 | 0.6 | 31.8 | 45.7 | 1100 |

| RNA2208.2RS | 530 | NA2208.2RS | 628 | 40 | 80 | 22.7 | 23 | 48 | 57 | 1.1 | 0.6 | 27.5 | 40.5 | 850 |

| RNA2209.2RS | 545 | NA2209.2RS | 655 | 45 | 85 | 22.7 | 23 | 52 | 62 | 1.1 | 0.6 | 28.5 | 43 | 800 |

| RNA2210.2RS | 563 | NA2210.2RS | 690 | 50 | 90 | 22.7 | 23 | 58 | 68 | 1.1 | 0.6 | 43.2 | 70 | 650 |

NATR… and NATV… series

| Bearing No. | Weight (g) |

Bearing No. | Weight (g) |

Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed (RPM) |

||||||

| d | D | B | C | d1 | r | Cr | Cor | |||||

| NATR 5 | 14 | NATR 5PP | 14 | 5 | 16 | 12 | 11 | 12 | 0.15 | 2.8 | 2.5 | 14000 |

| NATV 5 | 15 | NATV 5PP | 15 | 5 | 16 | 12 | 11 | 12 | 0.15 | 7 | 8.6 | 3800 |

| NATR 6 | 20 | NATR 6PP | 20 | 6 | 19 | 12 | 11 | 14 | 0.15 | 3.2 | 3.3 | 11000 |

| NATV 6 | 21 | NATV 6PP | 21 | 6 | 19 | 12 | 11 | 14 | 0.15 | 7.9 | 10.7 | 3100 |

| NATR 8 | 41 | NATR 8PP | 41 | 8 | 24 | 15 | 14 | 19 | 0.3 | 4.8 | 4.8 | 7500 |

| NATV 8 | 42 | NATV 8PP | 42 | 8 | 24 | 15 | 14 | 19 | 0.3 | 10.2 | 12.9 | 2500 |

| NATR 10 | 64 | NATR 10PP | 64 | 10 | 30 | 15 | 14 | 23 | 0.6 | 6.9 | 7 | 5500 |

| NATV 10 | 65 | NATV 10PP | 65 | 10 | 30 | 15 | 14 | 23 | 0.6 | 12.5 | 15.3 | 2100 |

| NATR 12 | 71 | NATR 12PP | 71 | 12 | 32 | 15 | 14 | 25 | 0.6 | 6.9 | 7.1 | 4500 |

| NATV 12 | 72 | NATV 12PP | 72 | 12 | 32 | 15 | 14 | 25 | 0.6 | 13.3 | 17 | 1800 |

| NATR 15 | 103 | NATR 15PP | 103 | 15 | 35 | 19 | 18 | 27 | 0.6 | 10.3 | 14.8 | 3600 |

| NATV 15 | 105 | NATV 15PP | 105 | 15 | 35 | 19 | 18 | 27 | 0.6 | 19.6 | 34.7 | 1600 |

| NATR 17 | 144 | NATR 17PP | 144 | 17 | 40 | 21 | 20 | 32 | 1 | 18.2 | 21.9 | 2900 |

| NATV 17 | 152 | NATV 17PP | 152 | 17 | 40 | 21 | 20 | 32 | 1 | 31.5 | 45.3 | 1400 |

| NATR 20 | 246 | NATR 20PP | 246 | 20 | 47 | 25 | 24 | 37 | 1 | 22.4 | 29.9 | 2400 |

| NATV 20 | 254 | NATV 20PP | 254 | 20 | 47 | 25 | 24 | 37 | 1 | 37.7 | 59.1 | 1300 |

| NATR 25 | 275 | NATR 25PP | 275 | 25 | 52 | 25 | 24 | 42 | 1 | 24 | 34.2 | 1800 |

| NATV 25 | 285 | NATV 25PP | 285 | 25 | 52 | 25 | 24 | 42 | 1 | 43 | 73.6 | 1000 |

| NATR 30 | 470 | NATR 30PP | 470 | 30 | 62 | 29 | 28 | 51 | 1 | 32.9 | 50.3 | 1300 |

| NATV 30 | 481 | NATV 30PP | 481 | 30 | 62 | 29 | 28 | 51 | 1 | 57.1 | 104 | 850 |

| NATR 35 | 635 | NATR 35PP | 635 | 35 | 72 | 29 | 28 | 58 | 1.1 | 34.4 | 55.8 | 1000 |

| NATV 35 | 647 | NATV 35PP | 647 | 35 | 72 | 29 | 28 | 58 | 1.1 | 59.3 | 114.5 | 750 |

| NATR 40 | 805 | NATR 40PP | 805 | 40 | 80 | 32 | 30 | 66 | 1.1 | 38.5 | 66.6 | 850 |

| NATV 40 | 890 | NATV 40PP | 890 | 40 | 80 | 32 | 30 | 66 | 1.1 | 70.8 | 149.1 | 650 |

| NATR 45 | 910 | NATR 45PP | 910 | 45 | 85 | 32 | 30 | 72 | 1.1 | 42.6 | 77.8 | 750 |

| NATV 45 | 935 | NATV 45PP | 935 | 45 | 85 | 32 | 30 | 72 | 1.1 | 74.5 | 164.4 | – |

| NATR 50 | 960 | NATR 50PP | 960 | 50 | 90 | 32 | 30 | 76 | 1.1 | 44.3 | 85.1 | 650 |

| NATV 50 | 990 | NATV 50PP | 990 | 50 | 90 | 32 | 30 | 76 | 1.1 | 78 | 179.8 | 550 |

NUTR… series

| Bearing No. | Weight (g) |

Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed (RPM) |

|||||||||

| d | D | B | C | d1 | r | rs1 | Cr | Cor | Fr perm | For perm | |||

| NUTR 15 | 99 | 15 | 35 | 19 | 18 | 20 | 0.6 | 0.3 | 22.7 | 26.2 | 8.6 | 16.8 | 6500 |

| NUTR 1542 | 158 | 15 | 42 | 19 | 18 | 20 | 0.6 | 0.3 | 22.7 | 26.2 | 21.9 | 21.9 | 6500 |

| NUTR 17 | 147 | 17 | 40 | 21 | 21 | 22 | 1 | 0.5 | 27.7 | 32.4 | 13.1 | 22.6 | 5500 |

| NUTR 1747 | 220 | 17 | 47 | 21 | 21 | 22 | 1 | 0.5 | 27.7 | 32.4 | 28 | 28 | 5500 |

| NUTR 20 | 245 | 20 | 47 | 25 | 24 | 27 | 1 | 0.5 | 39.7 | 44 | 16.4 | 33 | 4200 |

| NUTR 2052 | 321 | 20 | 52 | 25 | 24 | 27 | 1 | 0.5 | 39.7 | 44 | 38.5 | 41 | 4200 |

| NUTR 25 | 281 | 25 | 52 | 25 | 24 | 31 | 1 | 0.5 | 44.7 | 57.2 | 17.3 | 34.5 | 3400 |

| NUTR 2562 | 450 | 25 | 62 | 25 | 24 | 31 | 1 | 0.5 | 44.7 | 57.2 | 50 | 50 | 3400 |

| NUTR 30 | 465 | 30 | 62 | 29 | 28 | 38 | 1 | 0.5 | 63.7 | 89.7 | 23.5 | 46.5 | 2600 |

| NUTR 3072 | 697 | 30 | 72 | 29 | 28 | 38 | 1 | 0.5 | 63.7 | 89.7 | 64 | 64 | 2600 |

| NUTR 35 | 630 | 35 | 72 | 29 | 28 | 44 | 1.1 | 0.6 | 75.1 | 104.6 | 32 | 60 | 2100 |

| NUTR 3580 | 838 | 35 | 80 | 29 | 28 | 44 | 1.1 | 0.6 | 75.1 | 104.6 | 72 | 72 | 2100 |

| NUTR 40 | 816 | 40 | 80 | 32 | 30 | 51 | 1.1 | 0.6 | 90.4 | 131.1 | 30.5 | 60 | 1600 |

| NUTR 4090 | 1129 | 40 | 90 | 32 | 30 | 51 | 1.1 | 0.6 | 90.4 | 131.1 | 84 | 95 | 1600 |

| NUTR 45 | 883 | 45 | 85 | 32 | 30 | 55 | 1.1 | 0.6 | 95.5 | 144.4 | 31.5 | 61 | 1400 |

| NUTR 45100 | 1396 | 45 | 100 | 32 | 30 | 55 | 1.1 | 0.6 | 95.5 | 144.4 | 106 | 107 | 1400 |

| NUTR 50 | 950 | 50 | 90 | 32 | 30 | 60 | 1.1 | 0.6 | 97.2 | 161.4 | 32 | 62 | 1300 |

| NUTR 50110 | 1690 | 50 | 110 | 32 | 30 | 60 | 1.1 | 0.6 | 97.2 | 161.4 | 120 | 120 | 1300 |

KR… and KRE… series

KRV… and KRVE… series

| Bearing No. | Weight (g) |

Bearing No. | Weight (g) |

Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed | Eccentric Collar | Tightening Torque with Nut | |||||||||||||||

| D | d | C | r | B | B1 | B2 | G | G1 | M | M1 | C1 | d2 | Cr | Cor | (RPM) | d1 | B3 | e | Nm | ||||

| KR 16 | 18 | KRE 16 | 20 | 16 | 6 | 11 | 0.15 | 28 | 16 | – | M6×1 | 8 | 4 | – | 0.6 | 12 | 2.81 | 2.58 | 14000 | 9 | 7 | 0.5 | 3 |

| KRV 16 | 20 | KRVE 16 | 22 | 16 | 6 | 11 | 0.15 | 28 | 16 | – | M6×1 | 8 | 4 | – | 0.6 | 12 | 7.02 | 8.69 | 3800 | 9 | 7 | 0.5 | 3 |

| KR 19 | 28 | KRE 19 | 31 | 19 | 8 | 11 | 0.15 | 32 | 20 | – | M8×1.25 | 10 | 4 | – | 0.6 | 14 | 3.26 | 3.33 | 11000 | 11 | 9 | 0.5 | 8 |

| KRV 19 | 32 | KRVE 19 | 35 | 19 | 8 | 11 | 0.15 | 32 | 20 | – | M8×1.25 | 10 | 4 | – | 0.6 | 14 | 7.94 | 10.75 | 3100 | 11 | 9 | 0.5 | 8 |

| KR 22 | 44 | KRE 22 | 48 | 22 | 10 | 12 | 0.3 | 36 | 23 | – | M10×1 | 12 | 4 | – | 0.6 | 17 | 4.33 | 5.12 | 8000 | 13 | 10 | 0.5 | 15 |

| KRV 22 | 45 | KRVE 22 | 49 | 22 | 10 | 12 | 0.3 | 36 | 23 | – | M10×1 | 12 | 4 | – | 0.6 | 17 | 8.94 | 13.3 | 2600 | 13 | 10 | 0.5 | 15 |

| KR 26 | 58 | KRE 26 | 62 | 26 | 10 | 12 | 0.3 | 36 | 23 | – | M10×1 | 12 | 4 | – | 0.6 | 17 | 4.33 | 5.12 | 8000 | 13 | 10 | 0.5 | 15 |

| KRV 26 | 61 | KRVE 26 | 65 | 26 | 10 | 12 | 0.3 | 36 | 23 | – | M10×1 | 12 | 4 | – | 0.6 | 17 | 8.94 | 13.3 | 2600 | 13 | 10 | 0.5 | 15 |

| KR 30 | 87 | KRE 30 | 93 | 30 | 12 | 14 | 0.6 | 40 | 25 | 6 | M12×1.5 | 13 | 6 | 3 | 0.6 | 23 | 6.97 | 7.06 | 5500 | 15 | 11 | 0.5 | 22 |

| KRV 30 | 89 | KRVE 30 | 95 | 30 | 12 | 14 | 0.6 | 40 | 25 | 6 | M12×1.5 | 13 | 6 | 3 | 0.6 | 23 | 12.6 | 15.3 | 2100 | 15 | 11 | 0.5 | 22 |

| KR 32 | 98 | KRE 32 | 104 | 32 | 12 | 14 | 0.6 | 40 | 25 | 6 | M12×1.5 | 13 | 6 | 3 | 0.6 | 23 | 6.97 | 7.06 | 5500 | 15 | 11 | 0.5 | 22 |

| KRV 32 | 100 | KRVE 32 | 106 | 32 | 12 | 14 | 0.6 | 40 | 25 | 6 | M12×1.5 | 13 | 6 | 3 | 0.6 | 23 | 12.6 | 15.3 | 2100 | 15 | 11 | 0.5 | 22 |

| KR 35 | 169 | KRE 35 | 182 | 35 | 16 | 18 | 0.6 | 52 | 32.5 | 8 | M16×1.5 | 17 | 6 | 3 | 0.8 | 27 | 10.3 | 14.8 | 3600 | 20 | 14 | 1 | 58 |

| KRV 35 | 171 | KRVE 35 | 184 | 35 | 16 | 18 | 0.6 | 52 | 32.5 | 8 | M16×1.5 | 17 | 6 | 3 | 0.8 | 27 | 19.7 | 34.8 | 1600 | 20 | 14 | 1 | 58 |

| KR 40 | 247 | KRE 40 | 263 | 40 | 18 | 20 | 1 | 58 | 36.5 | 8 | M18×1.5 | 19 | 6 | 3 | 0.8 | 32 | 18.2 | 22 | 2900 | 22 | 16 | 1 | 87 |

| KRV 40 | 249 | KRVE 40 | 265 | 40 | 18 | 20 | 1 | 58 | 36.5 | 8 | M18×1.5 | 19 | 6 | 3 | 0.8 | 32 | 31.5 | 45.3 | 1400 | 22 | 16 | 1 | 87 |

| KR 47 | 386 | KRE 47 | 406 | 47 | 20 | 24 | 1 | 66 | 40.5 | 9 | M20×1.5 | 21 | 8 | 4 | 0.8 | 37 | 22.2 | 29.9 | 2400 | 24 | 18 | 1 | 120 |

| KRV 47 | 409 | KRVE 47 | 423 | 47 | 20 | 24 | 1 | 66 | 40.5 | 9 | M20×1.5 | 21 | 8 | 4 | 0.8 | 37 | 37.3 | 59.2 | 1400 | 24 | 18 | 1 | 120 |

| KR 52 | 461 | KRE 52 | 481 | 52 | 20 | 24 | 1 | 66 | 40.5 | 9 | M20×1.5 | 21 | 8 | 4 | 0.8 | 37 | 22.2 | 29.9 | 2400 | 24 | 18 | 1 | 120 |

| KRV 52 | 484 | KRVE 52 | 504 | 52 | 20 | 24 | 1 | 66 | 40.5 | 9 | M20×1.5 | 21 | 8 | 4 | 0.8 | 37 | 37.3 | 59.2 | 1300 | 24 | 18 | 1 | 120 |

| KR 62 | 790 | KRE 62 | 818 | 62 | 24 | 29 | 1 | 80 | 49.5 | 11 | M24×1.5 | 25 | 8 | 4 | 0.8 | 44 | 32.8 | 47.3 | 1900 | 28 | 22 | 1 | 220 |

| KRV 62 | 802 | KRVE 62 | 830 | 62 | 24 | 29 | 1 | 80 | 49.5 | 11 | M24×1.5 | 25 | 8 | 4 | 0.8 | 44 | 53.8 | 91 | 1100 | 28 | 22 | 1 | 220 |

| KR 72 | 1040 | KRE 72 | – | 72 | 24 | 29 | 1.1 | 80 | 49.5 | 11 | M24×1.5 | 25 | 8 | 4 | 0.8 | 44 | 32.8 | 47.3 | 1900 | 28 | 22 | 1 | 220 |

| KRV 72 | 1045 | KRVE 72 | – | 72 | 24 | 29 | 1.1 | 80 | 49.5 | 11 | M24×1.5 | 25 | 8 | 4 | 0.8 | 44 | 53.8 | 91 | 1100 | 28 | 22 | 1 | 220 |

| KR 80 | 1550 | KRE 80 | – | 80 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 8 | 4 | 1 | 53 | 48.2 | 83.9 | 1300 | 35 | 29 | 1.5 | 450 |

| KRV 80 | 1561 | KRVE 80 | – | 80 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 8 | 4 | 1 | 53 | 74.9 | 150.3 | 850 | 35 | 29 | 1.5 | 450 |

| KR 85 | – | KRE 85 | – | 85 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 8 | 4 | 1 | 53 | 48.2 | 83.9 | 1300 | 35 | 29 | 1.5 | 450 |

| KRV 85 | – | KRVE 85 | – | 85 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 8 | 4 | 1 | 53 | 74.9 | 150.3 | 850 | 35 | 29 | 1.5 | 450 |

| KR 90 | 1950 | KRE 90 | – | 90 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 8 | 4 | 1 | 53 | 48.2 | 83.9 | 1300 | 35 | 29 | 1.5 | 450 |

| KRV 90 | 1970 | KREV 90 | – | 90 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 8 | 4 | 1 | 53 | 74.9 | 150.3 | 850 | 35 | 29 | 1.5 | 450 |

NUKR… and NUKRE… series

| Bearing No. | Weight (g) |

Bearing No. | Weight (g) |

Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed | Eccentric Collar | Tightening Torque with Nut | |||||||||||||||||

| D | d | C | r | B | B1 | B2 | G | G1 | M1 | C1 | d2 | A/F | Cr | Cor | Fr perm | For perm | (RPM) | d1 | B3 | e | Nm | ||||

| NUKR 35 | 164 | – | – | 35 | 16 | 18 | 0.6 | 52 | 32.5 | 7.8 | M16×1.5 | 17 | 3 | 0.8 | 20 | 8 | 22.7 | 26.2 | 8.6 | 16.8 | 6500 | 20 | 12 | 1 | 58 |

| – | – | NUKRE 35 | 177 | 35 | 16 | 18 | 0.6 | 52 | 29.5 | 7.8 | M16×1.5 | 17 | 3 | 3.8 | 27 | 8 | 22.7 | 26.2 | 8.6 | 16.8 | 6500 | 20 | 12 | 1 | 58 |

| NUKR 40 | 242 | – | – | 40 | 18 | 20 | 1 | 58 | 36.5 | 8 | M18×1.5 | 19 | 3 | 0.8 | 22 | 8 | 27.7 | 32.4 | 13.1 | 22.6 | 5500 | 22 | 14 | 1 | 87 |

| – | – | NUKRE 40 | 258 | 40 | 18 | 20 | 1 | 58 | 33.5 | 8 | M18×1.5 | 19 | 3 | 3.8 | 30 | 8 | 27.7 | 32.4 | 13.1 | 22.6 | 5500 | 22 | 14 | 1 | 87 |

| NUKR 47 | 380 | NUKRE 47 | 400 | 47 | 20 | 24 | 1 | 66 | 40.5 | 9 | M20×1.5 | 21 | 4 | 0.8 | 27 | 10 | 39.7 | 44 | 16.4 | 33 | 4200 | 24 | 18 | 1 | 120 |

| NUKR 52 | 450 | NUKRE 52 | 470 | 52 | 20 | 24 | 1 | 66 | 40.5 | 9 | M20×1.5 | 21 | 4 | 0.8 | 31 | 10 | 44.7 | 55.2 | 17.3 | 34.5 | 3400 | 24 | 18 | 1 | 120 |

| NUKR 62 | 795 | NUKRE 62 | 824 | 62 | 24 | 28 | 1 | 80 | 49.5 | 11 | M24×1.5 | 25 | 4 | 1.3 | 38 | 14 | 63.7 | 89.7 | 23.5 | 46.5 | 2600 | 28 | 22 | 1 | 220 |

| NUKR 72 | 1571 | NUKRE 72 | 1050 | 72 | 24 | 28 | 1.1 | 80 | 49.5 | 11 | M24×1.5 | 25 | 4 | 1.3 | 44 | 14 | 74.1 | 104.6 | 32 | 60 | 2100 | 28 | 22 | 1 | 220 |

| NUKR 80 | 1600 | NUKRE 80 | 1670 | 80 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 4 | 1 | 47 | 14 | 107 | 141.4 | 47.5 | 96 | 1800 | 35 | 29 | 1.5 | 450 |

| NUKR 85 | 1790 | NUKRE 85 | 1860 | 85 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 4 | 1 | 47 | 14 | 107 | 141.4 | – | – | 1800 | 35 | 29 | 1.5 | 450 |

| NUKR 90 | 1960 | NUKRE 90 | 2571 | 90 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 4 | 1 | 47 | 14 | 107 | 141.4 | 77 | 117 | 1800 | 35 | 29 | 1.5 | 450 |

NAST…ZZ series

| Bearing No. | Weight (g) |

Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed | ||||||||

| d | D | B | C | d1 | a | e | r | Cr | Cor | (RPM) | ||

| NAST 6ZZ | 24.5 | 6 | 19 | 14 | 13.8 | 14 | 2.5 | 0.8 | 0.5 | 4.1 | 4.5 | 17000 |

| NAST 8ZZ | 39 | 8 | 24 | 14 | 13.8 | 17.5 | 2.5 | 0.8 | 1 | 5.7 | 5.9 | 14000 |

| NAST 10ZZ | 65 | 10 | 30 | 16 | 15.8 | 23.5 | 2.5 | 0.8 | 1.5 | 9.48 | 9.32 | 12000 |

| NAST 12ZZ | 75 | 12 | 32 | 16 | 15.8 | 25.5 | 2.5 | 0.8 | 1.5 | 10 | 10.4 | 11000 |

| NAST 15ZZ | 83 | 15 | 35 | 16 | 15.8 | 29 | 2.5 | 0.8 | 1.5 | 11.7 | 13.4 | 8500 |

| NAST 17ZZ | 136 | 17 | 40 | 20 | 19.8 | 32.5 | 3 | 1 | 1.5 | 19.2 | 23.5 | 7500 |

| NAST 20ZZ | 195 | 20 | 47 | 20 | 19.8 | 38 | 3 | 1 | 1.5 | 20.8 | 27 | 7000 |

| NAST 25ZZ | 226 | 25 | 52 | 20 | 19.8 | 43 | 3 | 1 | 1.5 | 23 | 32.5 | 5500 |

| NAST 30ZZ | 402 | 30 | 62 | 25 | 24.8 | 50.5 | 4 | 1.2 | 1.5 | 35.3 | 55.3 | 4500 |

| NAST 35ZZ | 550 | 35 | 72 | 25 | 24.8 | 53.5 | 4 | 1.2 | 1.5 | 36 | 58.3 | 4000 |

| NAST 40ZZ | 710 | 40 | 80 | 26 | 25.8 | 61.5 | 4 | 1.2 | 2 | 37.3 | 64.3 | 3500 |

| NAST 45ZZ | 760 | 45 | 85 | 26 | 25.8 | 66.5 | 4 | 1.2 | 2 | 37.3 | 66.3 | 3000 |

| NAST 50ZZ | 830 | 50 | 90 | 26 | 25.8 | 76 | 4 | 1.2 | 2 | 38.9 | 71.6 | 3000 |

PWTR…2RS series

| Bearing No. | Weight (g) |

Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed | |||||||||

| d | D | B | C | d1 | r | r1 | Cr | Cor | Fr perm | For perm | (RPM) | ||

| PWTR 15.2RS | 99 | 15 | 35 | 19 | 18 | 20 | 0.6 | 0.3 | 17.2 | 18.3 | 9.4 | 11.3 | 6000 |

| PWTR 1542.2RS | 158 | 15 | 42 | 19 | 18 | 20 | 0.6 | 0.3 | 17.2 | 18.3 | 14.1 | 14.1 | 6000 |

| PWTR 17.2RS | 147 | 17 | 40 | 21 | 21 | 22 | 1 | 0.5 | 19.4 | 20.8 | 13.8 | 13.8 | 5000 |

| PWTR 1747.2RS | 220 | 17 | 47 | 21 | 21 | 22 | 1 | 0.5 | 19.4 | 20.8 | 16.4 | 16.4 | 5000 |

| PWTR 20.2RS | 245 | 20 | 47 | 25 | 24 | 27 | 1 | 0.5 | 30.6 | 33.6 | 18.3 | 25.5 | 3800 |

| PWTR 2052.2RS | 321 | 20 | 52 | 25 | 24 | 27 | 1 | 0.5 | 30.6 | 33.6 | 29.5 | 29.5 | 3800 |

| PWTR 25.2RS | 281 | 25 | 52 | 25 | 24 | 31 | 1 | 0.5 | 34.4 | 40.8 | 19.3 | 28 | 3800 |

| PWTR 2562.2RS | 450 | 25 | 62 | 25 | 24 | 31 | 1 | 0.5 | 34.4 | 40.8 | 36 | 36 | 3800 |

| PWTR 30.2RS | 465 | 30 | 62 | 29 | 28 | 38 | 1 | 0.5 | 52.4 | 69.8 | 25.5 | 39.5 | 2200 |

| PWTR 3072.2RS | 697 | 30 | 72 | 29 | 28 | 38 | 1 | 0.5 | 52.4 | 69.8 | 49 | 49 | 2200 |

| PWTR 35.2RS | 630 | 35 | 72 | 29 | 28 | 44 | 1.1 | 0.6 | 61.8 | 81.4 | 34.5 | 46.5 | 1800 |

| PWTR 3580.2RS | 838 | 35 | 80 | 29 | 28 | 44 | 1.1 | 0.6 | 61.8 | 81.4 | 55 | 55 | 1800 |

| PWTR 40.2RS | 816 | 40 | 80 | 32 | 30 | 51 | 1.1 | 0.6 | 76 | 104.9 | 35 | 53 | 1500 |

| PWTR 4090.2RS | 1129 | 40 | 90 | 32 | 30 | 51 | 1.1 | 0.6 | 76 | 104.9 | 66 | 66 | 1500 |

| PWTR 45.2RS | 883 | 45 | 85 | 32 | 30 | 55 | 1.1 | 0.6 | 80.3 | 115.5 | 36 | 55 | 1300 |

| PWTR 45100.2RS | 1396 | 45 | 100 | 32 | 30 | 55 | 1.1 | 0.6 | 80.3 | 115.5 | 74 | 74 | 1300 |

| PWTR 50.2RS | 950 | 50 | 90 | 32 | 30 | 60 | 1.1 | 0.6 | 81.7 | 129 | 37 | 57 | 1100 |

| PWTR 50110.2RS | 1690 | 50 | 110 | 32 | 30 | 60 | 1.1 | 0.6 | 81.7 | 129 | 82 | 82 | 1100 |

KR52…NUUP series

| Bearing No. | Weight (g) |

Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed | ||||||||||||

| D | d | B | B1 | B2 | C | C1 | d1 | r | G | G1 | A/F | Cr | Cor | (RPM) | ||

| KR 5201 NUUP | 120 | 35 | 12 | 49.2 | 17 | 32.5 | 15.9 | 0.8 | 17.1 | 0.6 | M12×1.5 | 17 | 6 | 8.6 | 5.1 | 6000 |

| KR 5202 NUUP | 190 | 40 | 16 | 53.2 | 17 | 36.5 | 15.9 | 0.8 | 20 | 0.6 | M16×1.5 | 19 | 8 | 9.8 | 6.2 | 6000 |

| KR 5203 NUUP | 290 | 47 | 18 | 58.8 | 18.5 | 40.5 | 17.5 | 0.8 | 22.9 | 0.6 | M18×1.5 | 21 | 8 | 12.6 | 8.2 | 3800 |

| KR 5204 NUUP | 380 | 52 | 20 | 63.6 | 22.5 | 41.5 | 20.6 | 1.5 | 26.8 | 1 | M20×1.5 | 21 | 10 | 15.8 | 10.5 | 3800 |

| KR 5205 NUUP | 580 | 62 | 24 | 70.9 | 21.5 | 49.5 | 20.6 | 0.8 | 30.3 | 1 | M24×1.5 | 25 | 10 | 18.5 | 13 | 2200 |

| KR 5206 NUUP | 800 | 72 | 24 | 74.1 | 25 | 49.5 | 23.8 | 0.8 | 37.3 | 1 | M24×1.5 | 25 | 10 | 24.6 | 17.7 | 2200 |

| KR 5207 NUUP | 1200 | 80 | 30 | 91 | 28 | 63 | 27 | 1 | 42.4 | 1.1 | M30×1.5 | 32 | 12 | 30.5 | 22.4 | 1800 |

PWKR…2RS series

| Bearing No. | Weight (g) |

Bearing No. | Weight (g) |

Dimensions(mm) | Basic Load Rating(KN) | Limiting Speed | Eccentric Collar | Tightening Torque with Nut | |||||||||||||||||

| D | d | C | r | B | B1 | B2 | G | G1 | M1 | C1 | d2 | A/F | Cr | Cor | Fr pem | For pem | (RPM) | d1 | B3 | e | Nm | ||||

| PWKR35.2RS | 164 | – | – | 35 | 16 | 18 | 0.6 | 52 | 32.5 | 7.8 | M16×1.5 | 17 | 3 | 0.8 | 20 | 8 | 17.2 | 18.3 | 9.4 | 11.3 | 6000 | 20 | 12 | 1 | 58 |

| – | – | PWKRE35.2RS | 177 | 35 | 16 | 18 | 0.6 | 52 | 32.5 | – | M16×1.5 | 17 | – | 0.8 | 20 | 8 | 17.2 | 18.3 | 9.4 | 11.3 | 6000 | 20 | 12 | 1 | 58 |

| PWKR40.2RS | 242 | – | – | 40 | 18 | 20 | 1 | 58 | 36.5 | 8 | M18×1.5 | 19 | 3 | 0.8 | 22 | 8 | 19.4 | 20.8 | 13.8 | 13.8 | 5000 | 22 | 14 | 1 | 87 |

| – | – | PWKRE40.2RS | 258 | 40 | 18 | 20 | 1 | 58 | 36.5 | – | M18×1.5 | 19 | – | 0.8 | 22 | 8 | 19.4 | 20.8 | 13.8 | 13.8 | 5000 | 22 | 14 | 1 | 87 |

| PWKR47.2RS | 380 | PWKRE47.2RS | 400 | 47 | 20 | 24 | 1 | 66 | 40.5 | 9 | M20×1.5 | 21 | 4 | 0.8 | 27 | 10 | 30.6 | 33.6 | 19.3 | 25.5 | 3800 | 24 | 18 | 1 | 120 |

| PWKR52.2RS | 450 | PWKRE52.2RS | 470 | 52 | 20 | 24 | 1 | 66 | 40.5 | 9 | M20×1.5 | 21 | 4 | 0.8 | 31 | 10 | 34.4 | 40.8 | 19.3 | 28 | 3800 | 24 | 18 | 1 | 120 |

| PWKR62.2RS | 795 | PWKRE62.2RS | 824 | 62 | 24 | 28 | 1 | 80 | 49.5 | 11 | M24×1.5 | 25 | 4 | 1.3 | 38 | 14 | 52.4 | 69.8 | 25.5 | 39.5 | 2200 | 28 | 22 | 1 | 220 |

| PWKR72.2RS | 1571 | PWKRE72.2RS | 1050 | 72 | 24 | 28 | 1.1 | 80 | 49.5 | 11 | M24×1.5 | 25 | 4 | 1.3 | 44 | 14 | 61.8 | 81.4 | 46.5 | 46.5 | 2200 | 28 | 22 | 1 | 220 |

| PWKR80.2RS | 1600 | PWKRE80.2RS | 1670 | 80 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 4 | 1 | 47 | 14 | 93.9 | 118.9 | 53 | 70 | 1800 | 35 | 29 | 1.5 | 450 |

| PWKR85.2RS | 1780 | PWKRE85.2RS | 1850 | 85 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 4 | 1 | 47 | 14 | 93.9 | 118.9 | 53 | 70 | 1800 | 35 | 29 | 1.5 | 450 |

| PWKR90.2RS | 1960 | PWKRE90.2RS | 2571 | 90 | 30 | 35 | 1.1 | 100 | 63 | 15 | M30×1.5 | 32 | 4 | 1 | 47 | 14 | 93.9 | 118.9 | 82 | 82 | 1800 | 35 | 29 | 1.5 | |

| Our Main Products |

| Our Company |

HangZhou Flow Group Ltd is a professional manufacturer of bearings, collecting together production and processing, domestic and foreign trade. The factory specializes in the production and export of many kinds of bearings: deep groove ball bearing, spherical roller bearing, tapered roller bearing, and so on. The customized bearings is also acceptable and the production will be according to your requirements and samples.

All bearings in our factory adopt international quality standards. The complete equipment, strict quality control, advanced Japanese technology and quality service provide a guarantee to supply the high-quality bearings for our customers. Domestic sales and service network has covered 15 major cities in China, meanwhile our bearing has sold more than 60 overseas countries and regions.

Our bearings have been widely used in agriculture, textiles, mining, printing and packaging industries, in addition to applications in airports, air conditioning systems, conveyors and ship also applied.

If you are interested in any of our bearings or have an intention to order, please feel free to contact us.

| FAQ |

SAMPLES

1.Samples quantity: 1-10 pcs are available.

2.Free samples: It depends on the model NO., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3.It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1.MOQ: 10 pcs mix different standard bearings.

2.MOQ: 5000 pcs customized your brand bearings.

OEM POLICY

1.We can printing your brand (logo,artwork)on the shield or laser engraving your brand on the shield.

2.We can custom your packaging according to your design

3.All copyright own by clients and we promised don’t disclose any info.

SUPORT

Please visit our Clunt bearings website, we strongly encourge that you can communicate with us through email,thanks!

We have all kinds of bearings, just tell me your item number and quantity,best price will be offered to you soon

The material of the bearings, precision rating, seals type,OEM service,etc, all of them we can make according to your requiremen

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearing |

|---|---|

| The Number of Rows: | Double |

| Outer Dimension: | Medium and Large(120-190mm) |

| Material: | Bearing Steel |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Thrust Bearing |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does proper installation and alignment impact the performance and longevity of track bearings?

Proper installation and alignment play a critical role in the performance and longevity of track bearings. Correct installation ensures that the bearings are positioned and secured accurately, while proper alignment ensures that the load is distributed evenly and the bearings operate smoothly. Here’s an explanation of how proper installation and alignment impact the performance and longevity of track bearings:

Installation Impact:

- Load Distribution: Proper installation ensures that the track bearings are aligned and positioned correctly, allowing for even load distribution. When bearings are installed incorrectly, the load may be unevenly distributed, leading to excessive wear on certain parts of the bearings and reduced overall performance.

- Stability and Rigidity: Accurate installation provides stability and rigidity to the track bearings. Properly secured bearings minimize the risk of movement or vibration during operation, which can cause additional stress, premature wear, and potential damage to the bearings and surrounding components.

- Reduction of Misalignment: Correct installation minimizes the chances of misalignment between the track bearings and the track or guide rails. Misalignment can lead to uneven loading, increased friction, and accelerated wear and tear on the bearings. Proper alignment reduces these issues, ensuring smooth and efficient operation.

- Prevention of Contamination: During installation, it is important to take precautions to prevent contamination of the track bearings. Proper handling techniques, cleanliness, and the use of appropriate tools or protective measures help avoid introducing dirt, dust, or debris that can compromise the bearing’s performance and longevity.

Alignment Impact:

- Reduced Friction and Wear: Proper alignment of track bearings helps minimize friction and wear. When bearings are misaligned, excessive forces and irregular motion can occur, leading to increased friction and accelerated wear. Proper alignment ensures that the bearings operate within their intended design parameters, reducing friction and promoting longevity.

- Optimal Load Distribution: Correct alignment ensures that the load is distributed evenly across the track bearings. This prevents excessive stress on specific areas of the bearings, reducing the risk of premature failure and extending their service life. Optimal load distribution also contributes to smoother operation and improved overall performance.

- Minimized Noise and Vibration: Proper alignment helps minimize noise and vibration during operation. Misaligned track bearings can result in irregular motion, leading to unwanted noise and vibration that can affect the performance, comfort, and efficiency of the machinery or equipment. Proper alignment promotes smoother and quieter operation.

- Improved Efficiency: When track bearings are correctly aligned, the machinery or equipment experiences reduced resistance and improved efficiency. Misalignment can result in energy losses, increased power consumption, and decreased overall efficiency. Proper alignment ensures optimal power transfer and minimizes energy wastage.

It is important to follow the manufacturer’s guidelines and recommendations for the specific track bearings being installed. Proper installation techniques, including accurate positioning, secure fastening, and appropriate alignment, contribute to the optimal performance, reliability, and longevity of track bearings in various applications.

Can track bearings be used in both light-duty and heavy-duty machinery applications?

Yes, track bearings can be used in both light-duty and heavy-duty machinery applications. They are versatile components that offer reliable support for linear motion in a wide range of industrial settings. Here’s a detailed explanation:

1. Light-Duty Machinery Applications:

In light-duty machinery applications, track bearings provide cost-effective and efficient solutions for various tasks. Light-duty track bearings are designed to handle lower loads and are commonly used in applications such as:

- Office automation equipment

- Consumer electronics

- Printing machinery

- Small conveyors and material handling systems

- Automated vending machines

- Textile machinery

These applications typically involve lighter loads and lower operating speeds, making light-duty track bearings suitable for providing smooth and reliable linear motion.

2. Heavy-Duty Machinery Applications:

Track bearings are also widely used in heavy-duty machinery applications that require robust components capable of handling substantial loads and challenging operating conditions. Heavy-duty track bearings are designed to withstand higher loads and offer increased durability. They are commonly employed in applications such as:

- Material handling equipment

- Construction machinery

- Mining equipment

- Transportation systems

- Industrial automation

- Large-scale conveyors

- Steel mills

These applications often involve heavy loads, high operating speeds, and demanding environments. Track bearings in heavy-duty machinery applications are engineered to provide reliable performance, extended service life, and resistance to factors such as contamination, shock, and vibration.

Track bearings are available in various sizes, designs, and load capacities, allowing them to be tailored to the specific requirements of both light-duty and heavy-duty machinery applications. Manufacturers offer a range of options to accommodate different load capacities, operating conditions, and performance specifications.

It is important to consider the specific requirements and operating conditions of the machinery application when selecting track bearings. Consulting with bearing manufacturers or industry experts can help ensure the appropriate track bearings are chosen for optimal performance and reliability in both light-duty and heavy-duty machinery applications.

How do track bearings contribute to smooth and precise motion in machinery and equipment?

Track bearings play a crucial role in enabling smooth and precise motion in machinery and equipment. They provide support and guidance for moving components, allowing them to move along tracks or guide rails with minimal friction and accurate positioning. Let’s explore how track bearings contribute to smooth and precise motion:

- Reduced Friction: Track bearings are designed to minimize friction between the rolling elements (such as balls or rollers) and the raceways (inner and outer rings). By reducing friction, track bearings help to minimize energy losses, prevent excessive heat generation, and extend the lifespan of the bearing and other components in the system. Low friction enables smoother and more efficient motion, resulting in improved overall performance.

- Accuracy and Precision: Track bearings are manufactured to precise tolerances, ensuring consistent dimensions and smooth surfaces. This precision contributes to accurate and repeatable positioning of the moving components along the track or guide rail. It allows machinery and equipment to achieve the desired motion with minimal deviation or backlash, enabling precise control and operation.

- Load Distribution: Track bearings are designed to distribute loads evenly across the rolling elements and raceways. This load distribution helps prevent localized stress concentrations and ensures that the applied loads are shared by multiple contact points. By distributing the loads effectively, track bearings enhance the stability and integrity of the moving components, reducing the risk of premature wear or failure.

- Guidance and Alignment: Track bearings provide guidance and alignment for the moving components. They help maintain the desired orientation and position of the components along the track or guide rail, preventing misalignment and unwanted movements. This guidance ensures smooth and precise motion, minimizing vibrations, noise, and the risk of component damage or malfunction.

- Shock and Impact Absorption: Track bearings are designed to absorb shocks and impacts that may occur during operation. They help cushion the effects of sudden loads or vibrations, protecting the moving components and reducing the transmission of these forces to the rest of the machinery or equipment. This shock absorption capability contributes to smoother and more stable motion, enhancing overall performance and reliability.

By incorporating high-quality track bearings into machinery and equipment, engineers can achieve smooth and precise motion, improving the efficiency, accuracy, and longevity of the system. Proper selection, installation, and maintenance of track bearings are essential to ensure optimal performance and to minimize the risk of issues such as excessive wear, misalignment, or loss of motion control.

editor by CX 2024-05-09