Product Description

These bearings are capable of taking high radial loads and axial loads in 1 direction. In the HR series, the rollers are increased in both size and number giving it an even higher load capacity. They are generally mounted in pairs in a manner similar to single-row angular contact ball bearings. In this case, the proper internal clearance can be obtained by adjusting the axial distance between the cones or cups of the 2 opposed bearings.

| Model | Size | Rated dynamic load (KN) | Rated static load (KN) | Weight (kg) | ||

| (mm) | ||||||

| d | D | T | ||||

| 32007 | 35 | 62 | 18 | 43.2 | 59.2 | 0.224 |

| 32008 | 40 | 68 | 19 | 51.9 | 71.1 | 0.268 |

| 32009 | 45 | 75 | 20 | 58.4 | 81.4 | 0.339 |

| 32571 | 50 | 80 | 20 | 61.1 | 89 | 0.367 |

| 32011 | 55 | 90 | 23 | 80.2 | 117.2 | 0.564 |

| 32012 | 60 | 95 | 23 | 81.7 | 122.2 | 0.597 |

| 32013 | 65 | 100 | 23 | 82.8 | 127.3 | 0.628 |

| 32014 | 70 | 110 | 25 | 104.3 | 160.1 | 0.838 |

| 32015 | 75 | 115 | 25 | 103.1 | 160.2 | 0.875 |

| 32016 | 80 | 125 | 29 | 141 | 220 | 1.27 |

| 32017 | 85 | 130 | 29 | 139.8 | 220.3 | 1.33 |

| 32018 | 90 | 140 | 32 | 171.3 | 271 | 1.77 |

| 32019 | 95 | 145 | 32 | 174.6 | 281.3 | 1.796 |

| 32571 | 100 | 150 | 32 | 173.1 | 281.7 | 1.91 |

| 32571 | 105 | 160 | 35 | 205. 4 | 335.8 | 2.4 |

| 32571 | 110 | 170 | 38 | 245.7 | 403.4 | 3.02 |

| 32571 | 120 | 180 | 38 | 242.1 | 404.4 | 3.18 |

| 32026 | 130 | 200 | 45 | 333.7 | 567.1 | 4.94 |

| 32571 | 140 | 210 | 45 | 329.8 | 567.8 | 5.15 |

| 32030 | 150 | 225 | 48 | 367.6 | 635.8 | 6.25 |

| 32032 | 160 | 240 | 51 | 419.6 | 734.5 | 7.66 |

| 32207 | 35 | 72 | 24.25 | 70.6 | 89.5 | 0.426 |

| 32208 | 40 | 80 | 24.75 | 77.9 | 97.2 | 0.529 |

| 32209 | 45 | 85 | 24.75 | 80.7 | 104 | 0.587 |

| 32210 | 50 | 90 | 24.75 | 82.8 | 107.6 | 0.654 |

| 32211 | 55 | 100 | 26.75 | 108 | 142.3 | 0.881 |

| 32212 | 60 | 110 | 29.75 | 132.8 | 179.6 | 1.17 |

| 32213 | 65 | 120 | 32.75 | 160.9 | 221.7 | 1.58 |

| 32214 | 70 | 125 | 33.25 | 168.5 | 237.1 | 1.66 |

| 32215 | 75 | 130 | 33.25 | 170.3 | 242.1 | 1.76 |

| 32216 | 80 | 140 | 35.25 | 198.1 | 279 | 2.19 |

| 32217 | 85 | 150 | 38.5 | 226.7 | 324 | 2.7 |

| 32218 | 90 | 160 | 42.5 | 269.8 | 395.5 | 3.61 |

| 32219 | 95 | 170 | 45.5 | 302.5 | 448.4 | 4.34 |

| 32220 | 100 | 180 | 49 | 341 | 512 | 5.31 |

| 32221 | 105 | 190 | 53 | 342 | 517 | 6.37 |

| 32222 | 110 | 200 | 56 | 388 | 590 | 7.45 |

| 32224 | 120 | 215 | 61.5 | 420 | 610 | 9.04 |

| 32226 | 130 | 230 | 67.75 | 551.7 | 888.7 | 11.377 |

| 32228 | 140 | 250 | 71.75 | 643.7 | 1049.3 | 14.413 |

| 32307 | 35 | 80 | 32.75 | 99 | 118.3 | 0.766 |

| 32308 | 40 | 90 | 35.25 | 115.7 | 147.8 | 1 |

| 32309 | 45 | 100 | 38.25 | 145.3 | 189.4 | 1.41 |

| 32310 | 50 | 110 | 42.25 | 177.5 | 236.1 | 1.9 |

| 32311 | 55 | 120 | 45.5 | 203.1 | 271.4 | 2.33 |

| 32312 | 60 | 130 | 48.5 | 226.7 | 303 | 2.96 |

| 32313 | 65 | 140 | 51 | 259.6 | 349.8 | 3.53 |

| 32314 | 70 | 150 | 54 | 298.9 | 408.5 | 4.41 |

| 32315 | 75 | 160 | 58 | 347.4 | 483.1 | 5.27 |

| 32316 | 80 | 170 | 61.5 | 387.9 | 543.1 | 6.43 |

| 32317 | 85 | 180 | 63.5 | 421.8 | 592.8 | 7.31 |

| 32318 | 90 | 190 | 67.5 | 478.2 | 693.3 | 8.81 |

| 32319 | 95 | 200 | 71.5 | 516.1 | 737.7 | 10.1 |

| 32320 | 100 | 215 | 77.5 | 600.1 | 872.2 | 13 |

| 35717 | 35 | 72 | 18.25 | 54.2 | 63.5 | 0.333 |

| 35718 | 40 | 80 | 19.75 | 63 | 74 | 0.431 |

| 35719 | 45 | 85 | 20.75 | 67.9 | 83.6 | 0.474 |

| 35710 | 50 | 90 | 21.75 | 73.3 | 92.1 | 0.529 |

| 35711 | 55 | 100 | 22.75 | 90.8 | 113.7 | 0.713 |

| 35712 | 60 | 110 | 23.75 | 103.3 | 130 | 0.923 |

| 35713 | 65 | 120 | 24.75 | 120.6 | 152.6 | 1.58 |

| 35714 | 70 | 125 | 26.25 | 132.3 | 173.6 | 1.29 |

| 35715 | 75 | 130 | 27.25 | 138.4 | 185.4 | 1.4 |

| 35716 | 80 | 140 | 28.25 | 160.4 | 212.8 | 1.56 |

| 35717 | 85 | 150 | 30.5 | 177.6 | 236.8 | 2.06 |

| 35718 | 90 | 160 | 32.5 | 200.1 | 269.6 | 2.54 |

| 35719 | 95 | 170 | 34.5 | 226.6 | 309 | 3.04 |

| 35710 | 100 | 180 | 37 | 253.9 | 350.3 | 3.72 |

| 35711 | 105 | 190 | 39 | 285.3 | 398.6 | 4.38 |

| 35712 | 110 | 200 | 41 | 314.9 | 443.6 | 5.21 |

| 35714 | 120 | 215 | 43.5 | 337.4 | 483.3 | 6.2 |

| 35716 | 130 | 230 | 43.75 | 366 | 521.4 | 6.94 |

| 35718 | 140 | 250 | 45.75 | 409.2 | 584.7 | 8.73 |

| 35710 | 150 | 270 | 49 | 451.2 | 645.9 | 10.8 |

| 30306 | 30 | 72 | 20.75 | 59.6 | 60.1 | 0.389 |

| 30307 | 35 | 80 | 22.75 | 75.3 | 82.6 | 0.515 |

| 30308 | 40 | 90 | 25.25 | 80.5 | 90.2 | 0.761 |

| 30309 | 45 | 100 | 27.25 | 113 | 128 | 0.984 |

| 3571 | 50 | 110 | 29.25 | 145.3 | 189 | 1.26 |

| 3571 | 55 | 120 | 31.5 | 153.5 | 187.6 | 1.65 |

| 3571 | 60 | 130 | 33.5 | 171.4 | 210 | 1.96 |

| 3571 | 65 | 140 | 36 | 193 | 227 | 2.42 |

| 3571 | 70 | 150 | 38 | 219 | 271.7 | 3.04 |

| 3571 | 75 | 160 | 40 | 252.8 | 318.8 | 3.71 |

| 3 0571 | 80 | 170 | 42.5 | 278.8 | 352.5 | 4.27 |

| 3 0571 | 85 | 180 | 44.5 | 304.9 | 388.2 | 4.96 |

| 3 0571 | 90 | 190 | 46.5 | 342.1 | 440.9 | 5.8 |

| 3571 | 95 | 200 | 49.5 | 369 | 477.7 | 6.8 |

| 30320 | 100 | 215 | 51.5 | 406.4 | 526.4 | 8.22 |

| 33008 | 40 | 68 | 22 | 60.2 | 79.6 | 0.306 |

| 33009 | 45 | 75 | 24 | 72.6 | 100.4 | 0.398 |

| 33571 | 50 | 80 | 24 | 76.8 | 110.9 | 0.433 |

| 33011 | 55 | 90 | 27 | 94.9 | 144.7 | 0.651 |

| 33012 | 60 | 95 | 27 | 96.7 | 151.1 | 0.691 |

| 33013 | 65 | 100 | 27 | 98.1 | 157.7 | 0.732 |

| 33014 | 70 | 110 | 31 | 134.4 | 220.4 | 1.07 |

| 33015 | 75 | 115 | 31 | 133.1 | 221.2 | 1.12 |

| 33016 | 80 | 125 | 36 | 181.9 | 304.3 | 1.63 |

| 33017 | 85 | 130 | 36 | 180.4 | 305.5 | 1.69 |

| 33018 | 90 | 140 | 39 | 232.6 | 388.6 | 2.2 |

| 33019 | 95 | 145 | 39 | 231 | 389.9 | 2.26 |

| 33571 | 100 | 150 | 39 | 229.5 | 391.2 | 2.33 |

| 33571 | 105 | 160 | 43 | 257.4 | 437.4 | 2.97 |

| 33571 | 110 | 170 | 47 | 288.7 | 502.7 | 3.74 |

| 33571 | 120 | 180 | 48 | 298.2 | 535.1 | 4.07 |

| 33026 | 130 | 200 | 55 | 400.6 | 727.4 | 6.14 |

| 33571 | 140 | 210 | 56 | 407 | 755.5 | 6.57 |

| 33030 | 150 | 225 | 59 | 461.2 | 873.8 | 7.98 |

| 33108 | 40 | 75 | 26 | 84.7 | 110.3 | 0.496 |

| 33109 | 45 | 80 | 26 | 87.1 | 117.2 | 0.535 |

| 33110 | 50 | 85 | 26 | 89.3 | 124.1 | 0.572 |

| 33111 | 55 | 95 | 30 | 114.5 | 164.8 | 0.483 |

| 33112 | 60 | 100 | 30 | 117.1 | 173.2 | 0.895 |

| 33113 | 65 | 110 | 34 | 142.8 | 220.4 | 1.3 |

| 33114 | 70 | 120 | 37 | 172.1 | 267 | 1.7 |

| 33115 | 75 | 125 | 37 | 176.1 | 279.6 | 1.78 |

| 33116 | 80 | 130 | 37 | 179.6 | 292.3 | 1.87 |

| 33117 | 85 | 140 | 41 | 215.7 | 354.2 | 2.43 |

| 33118 | 90 | 150 | 45 | 252.1 | 414.7 | 3.13 |

| 33119 | 95 | 160 | 49 | 298.9 | 498.2 | 3.94 |

| 33120 | 100 | 165 | 52 | 309.4 | 529.2 | 4.31 |

| 33121 | 105 | 175 | 56 | 351.8 | 607.8 | 5.29 |

| 33122 | 110 | 180 | 56 | 373.2 | 639.1 | 5.5 |

| 33124 | 120 | 200 | 62 | 448.2 | 779.1 | 7.68 |

| 33207 | 35 | 72 | 28 | 82.6 | 101.7 | 0.515 |

| 33208 | 40 | 80 | 32 | 105.8 | 135.5 | 0.715 |

| 33209 | 45 | 85 | 32 | 109.5 | 145.1 | 0.771 |

| 33210 | 50 | 90 | 32 | 112.9 | 154.6 | 0.825 |

| 33211 | 55 | 100 | 35 | 35 | 196.7 | 1.15 |

| 33212 | 60 | 110 | 38 | 38 | 231.4 | 1.51 |

| 33213 | 65 | 120 | 41 | 41 | 281.6 | 1.99 |

| 33214 | 70 | 125 | 41 | 41 | 298.3 | 2.1 |

| 33215 | 75 | 130 | 41 | 41 | 299.7 | 2.17 |

| 33216 | 80 | 140 | 46 | 46 | 361.8 | 2.83 |

| 33217 | 85 | 150 | 49 | 49 | 415.7 | 3.52 |

| 33218 | 90 | 160 | 55 | 55 | 499.7 | 4.55 |

| 33219 | 95 | 170 | 58 | 58 | 568.4 | 5.48 |

| 33220 | 100 | 180 | 63 | 63 | 666.2 | 6.71 |

| 33221 | 105 | 190 | 68 | 68 | 770.5 | 8.12 |

| 32909 | 45 | 68 | 15 | 32 | 48.4 | 0.18 |

| 32910 | 50 | 72 | 15 | 36.9 | 56.1 | 0.181 |

| 32911 | 55 | 80 | 17 | 41.5 | 66.7 | 0.262 |

| 32912 | 60 | 85 | 17 | 46.1 | 73.1 | 0.279 |

| 32913 | 65 | 90 | 17 | 45.4 | 73.2 | 0.295 |

| 32914 | 70 | 100 | 20 | 70.8 | 114.7 | 0.471 |

| 32915 | 75 | 105 | 20 | 78.2 | 124.7 | 0.49 |

| 32916 | 80 | 110 | 20 | 79.3 | 129 | 0.514 |

| 32917 | 85 | 120 | 23 | 96.9 | 164.1 | 0.767 |

| 32918 | 90 | 125 | 23 | 95.8 | 164.5 | 0.798 |

| 32919 | 95 | 130 | 23 | 97.1 | 169.8 | 0.931 |

| 32920 | 100 | 140 | 25 | 126.6 | 218.4 | 1.12 |

| 32921 | 105 | 145 | 25 | 128 | 255.6 | 1.16 |

| 32922 | 110 | 150 | 25 | 129.7 | 232.6 | 1.2 |

| 32924 | 120 | 165 | 29 | 171.9 | 317.3 | 1.78 |

| 32926 | 130 | 180 | 32 | 206 | 380.6 | 2.34 |

| 32928 | 140 | 190 | 32 | 207.2 | 392.4 | 2.47 |

| 32930 | 150 | 210 | 38 | 261 | 510.4 | 3.87 |

| 32932 | 160 | 220 | 38 | 262.8 | 525.4 | 4.07 |

| 32934 | 170 | 230 | 38 | 280.1 | 561.5 | 4.33 |

ZheJiang REET BEARING.CO.,LTD is a professional bearing manufacturer and exporter.

We have a wealth of technical.All producing processes are finished in our manufactory. As an ISO9001:2000 certified manufacturer,we will solve various problems in application and use of our bearings.

Our company is an authorized distributor of FAG, INA, CZPT and other world brand bearings.Our company has the right to self-export bearings and launches its own brand RTB.

Our bearing had been exported to more than 20 countries worldwide and are warmly welcomed.

We’re looking forward to your order.

FAQ

1.Is the company a production factory or a trading company?

ZheJiang REET BEARING CO.,LTD is a manufacturing enterprise focusing on bearings and integrating research, production and sales.

2.How many the MOQ of your company?

Depending on the size of the bearing, the MOQ is variable, if you are interested, you can contact me for a quote.

3.Does the company accept OEM or customized bearings?

In addition to standard products, we also supply non-standard and modified standard products for special application. Meanwhile, we provide OEM service.

4.Can the company provide free samples?

We can provide samples for free. You only need to provide shipping.

5.What are the company’s delivery terms?

We can accept EXW,FOB,CFR,CIF,etc. You can choose the 1 which is the most convenient cost effective for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rated Dynamic Load: | 139.8 |

|---|---|

| Rated Static Load: | 220.3 |

| Weight: | 1.33 |

| Rolling Body: | Roller Bearings |

| The Number of Rows: | Single |

| Material: | Bearing Steel |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you explain the maintenance and lubrication requirements for track bearings?

Maintenance and lubrication are essential aspects of ensuring the optimal performance and longevity of track bearings. Proper maintenance practices and appropriate lubrication help minimize wear, reduce friction, prevent corrosion, and extend the service life of the bearings. Here’s an explanation of the maintenance and lubrication requirements for track bearings:

Maintenance Requirements:

- Cleanliness: It is crucial to maintain a clean operating environment for track bearings. Regularly remove dirt, dust, and debris from the track and bearing surfaces to prevent contamination, which can lead to premature wear and damage.

- Inspection: Periodically inspect the track bearings for signs of wear, damage, or misalignment. Check for excessive play, noise, or roughness during operation. If any issues are detected, take appropriate measures such as bearing replacement or realignment to ensure optimal performance.

- Tightening and Fasteners: Check the tightness of fasteners, such as bolts or screws, that secure the track bearings. Loose fasteners can lead to misalignment or instability. Ensure that all fasteners are properly tightened according to the manufacturer’s specifications.

- Track Alignment: Proper track alignment is crucial for smooth and efficient operation of track bearings. Regularly check the alignment of the track or guide rails and make necessary adjustments to maintain proper alignment, minimizing excessive loads and wear on the bearings.

- Load Limits: Adhere to the specified load limits for the track bearings. Exceeding the recommended load capacity can cause premature wear and failure. Consider the dynamic and static load ratings of the bearings to ensure they are not subjected to excessive loads that can compromise their performance.

Lubrication Requirements:

- Proper Lubricant Selection: Select the appropriate lubricant based on the operating conditions, such as temperature, load, and speed. Consult the manufacturer’s recommendations or seek expert advice to ensure the lubricant’s compatibility with the track bearings and the specific application.

- Regular Lubrication: Follow a regular lubrication schedule as recommended by the manufacturer. This may involve applying lubricant at specified intervals or based on the operating hours. Adequate lubrication helps minimize friction, reduce wear, and maintain proper functioning of the track bearings.

- Correct Lubrication Method: Apply the lubricant using the appropriate method, whether it’s manual greasing, automatic lubrication systems, or specialized lubrication techniques. Ensure that the lubricant reaches all necessary contact points and provides sufficient coverage to the bearing surfaces.

- Monitoring and Replenishment: Monitor the lubricant levels regularly and replenish as needed. In some cases, track bearings may have built-in lubrication systems that require periodic refilling or maintenance. Keep track of the lubricant condition and replace it when it becomes contaminated or degraded.

- Environmental Considerations: Consider the operating environment when selecting the lubricant. Extreme temperatures, exposure to moisture, or the presence of chemicals or contaminants may require special lubricants that can withstand these conditions and provide effective protection and lubrication.

It is important to consult the manufacturer’s guidelines and recommendations specific to the track bearings being used. Following the recommended maintenance and lubrication practices ensures optimal performance, reduces the risk of premature failure, and maximizes the overall lifespan of the track bearings.

How do track bearings enhance the overall efficiency and functionality of linear motion systems?

Track bearings play a crucial role in enhancing the overall efficiency and functionality of linear motion systems. They offer several benefits that contribute to improved performance, increased reliability, and enhanced functionality. Here’s a detailed explanation:

- Reduced Friction: Track bearings are designed to minimize friction between moving components, allowing for smoother and more efficient linear motion. By reducing friction, they help to optimize the efficiency of the system, reducing energy consumption and minimizing wear on the components.

- Precision and Stability: Track bearings provide precise guidance and stability to the linear motion system. They ensure accurate and repeatable motion along the intended path, allowing for precise positioning and control. This is particularly important in applications that require high accuracy, such as CNC machines, robotics, and automated assembly lines.

- Load Distribution: Track bearings distribute the load evenly along their length, allowing for efficient load transfer and reducing the concentration of forces on specific components. This helps to prevent excessive wear, deformation, and premature failure of the system, improving overall reliability and longevity.

- Handling Heavy Loads: Track bearings are specifically designed to handle heavy loads in linear motion systems. They offer high load capacities and robust construction, enabling them to support and move heavy objects with ease. This capability is essential in industries such as material handling, construction, and transportation.

- Smooth and Quiet Operation: Track bearings are engineered to provide smooth and quiet operation, minimizing noise and vibrations in the linear motion system. This is especially important in applications where noise reduction and comfort are critical, such as in medical equipment, office automation, and consumer electronics.

- Versatility and Adaptability: Track bearings come in various designs, sizes, and configurations to accommodate different linear motion system requirements. They can be easily integrated into existing systems or customized to fit specific applications. This versatility allows for greater flexibility and adaptability in designing and implementing linear motion solutions.

- Maintenance and Serviceability: Track bearings are designed for ease of maintenance and serviceability. They often feature removable components, such as seals or shields, that allow for inspection, cleaning, and lubrication. This simplifies maintenance tasks and reduces downtime, contributing to improved overall system efficiency and uptime.

By incorporating track bearings into linear motion systems, industries can benefit from increased efficiency, improved performance, and enhanced functionality. Whether it’s achieving precise positioning, handling heavy loads, reducing friction, or ensuring smooth operation, track bearings play a vital role in optimizing the overall efficiency and functionality of linear motion systems.

Can you explain the different types of track bearings used in industrial and mechanical systems?

Track bearings, also known as track rollers or track follower bearings, come in various types to suit different industrial and mechanical system requirements. Let’s explore the different types of track bearings commonly used in these applications:

- Yoke Type Track Rollers: Yoke type track rollers are a popular type of track bearing characterized by their thick outer rings. They are designed to handle high radial loads and moderate axial loads. Yoke type track rollers feature an inner ring with a stud for mounting on a shaft or stud. They are widely used in applications such as conveyors, cam mechanisms, material handling systems, and agricultural machinery.

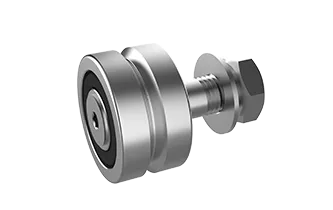

- Stud Type Track Rollers: Stud type track rollers are similar to yoke type track rollers but lack an inner ring. Instead, they have a stud that serves as the mounting component. Stud type track rollers are suitable for applications with limited space or where the outer ring can be directly mounted onto a mating surface. They are commonly used in applications such as cam mechanisms, indexing equipment, and tensioning systems.

- Cam Followers: Cam followers, also known as cam bearings or track followers, are track bearings designed specifically for cam-driven systems. They have a stud or shaft for mounting and a built-in roller or needle bearing. Cam followers follow the profile of a cam, converting the rotary motion of the cam into linear or oscillating motion. They are used in applications such as printing presses, packaging machinery, textile machinery, and automotive engines.

- Guiding Track Rollers: Guiding track rollers are track bearings designed to provide precise and guided linear motion. They feature a thick outer ring with a track or guide surface. Guiding track rollers are commonly used in material handling systems, conveyor systems, and automated machinery to facilitate smooth and controlled movement along a track or guide rail.

- V-Groove Track Rollers: V-groove track rollers have a specialized V-shaped groove on the outer ring. This groove allows the rollers to run on V-shaped tracks or rails, providing accurate alignment and guidance. V-groove track rollers are used in applications such as track systems, sliding gates, and linear motion guides.

- Flanged Track Rollers: Flanged track rollers feature an additional flange on the outer ring. The flange helps in axial guidance and prevents the track roller from shifting or tilting under axial loads. Flanged track rollers are commonly used in applications such as cam mechanisms, linear motion systems, and conveyor systems.

- Idler Track Rollers: Idler track rollers are non-powered track rollers used to support and guide conveyor belts, chains, or other moving components. They are typically used in material handling systems, conveyor systems, and packaging machinery.

These different types of track bearings offer versatility and flexibility in industrial and mechanical systems. Depending on the specific application requirements, engineers and designers can select the most suitable type of track bearing to ensure smooth motion, reliable operation, and efficient load support. The choice of track bearing type depends on factors such as load capacity, space constraints, track configuration, and environmental conditions.

editor by CX 2024-04-03