Product Description

Product Description

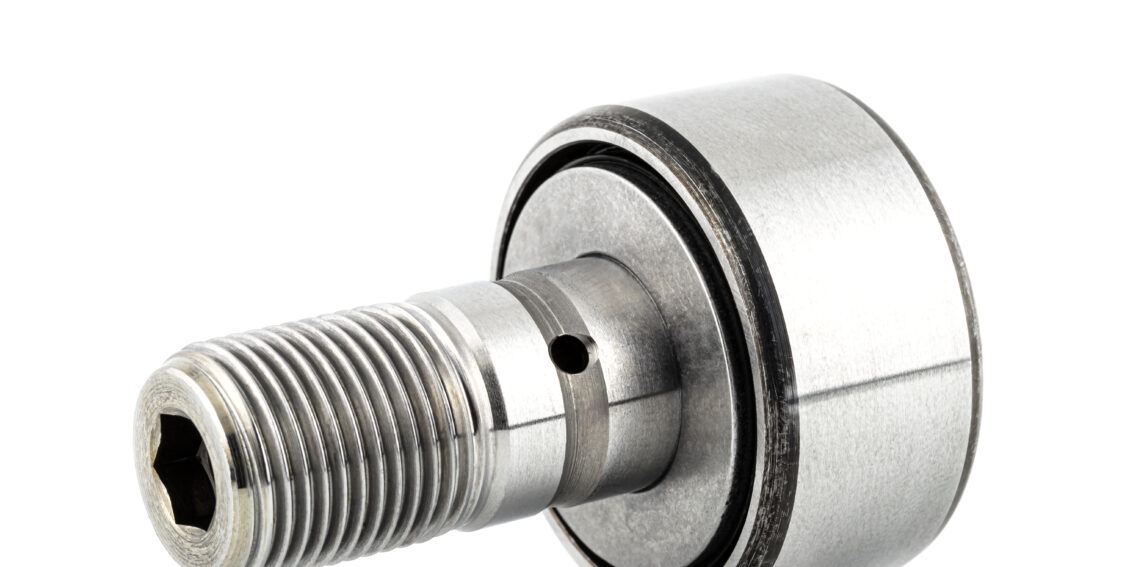

A needle roller bearing is a special type of roller bearing which uses long, thin cylindrical rollers resembling needles. Ordinary roller bearings’ rollers are only slightly longer than their diameter, but needle bearings typically have rollers that are at least 4 times longer than their diameter.

|

Product name |

neddle bearing |

|

Condition |

New |

|

Warranty |

1 year |

|

Applicable Industries |

Building industry machinery |

|

Video outgoing-inspection |

Available |

|

Machinery Test Report |

Available |

|

Marketing Type |

New Product 2571 |

|

Warranty of core components |

1 year |

|

Core Components |

Bearing |

|

Place of Origin |

China,ZHangZhoug |

|

Quality |

Large bearing capacity,high speed,low noise. |

|

Brand Name |

SHAC |

|

Material |

Steel |

|

service |

ODM/OEM |

Product Parameters

Detailed Photos

Company Profile

Certifications

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.you have to pay for the shipping cost.If you need many items, or need more qty for each item,we will charge for the samples.

To get price list of linear gudies, please contact us.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Cage: | With Cage |

|---|---|

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Style: | With Outer Ring |

| Material: | Bearing Steel |

| Type: | Closed |

| Samples: |

US$ 3/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does proper installation and alignment impact the performance and longevity of track bearings?

Proper installation and alignment play a critical role in the performance and longevity of track bearings. Correct installation ensures that the bearings are positioned and secured accurately, while proper alignment ensures that the load is distributed evenly and the bearings operate smoothly. Here’s an explanation of how proper installation and alignment impact the performance and longevity of track bearings:

Installation Impact:

- Load Distribution: Proper installation ensures that the track bearings are aligned and positioned correctly, allowing for even load distribution. When bearings are installed incorrectly, the load may be unevenly distributed, leading to excessive wear on certain parts of the bearings and reduced overall performance.

- Stability and Rigidity: Accurate installation provides stability and rigidity to the track bearings. Properly secured bearings minimize the risk of movement or vibration during operation, which can cause additional stress, premature wear, and potential damage to the bearings and surrounding components.

- Reduction of Misalignment: Correct installation minimizes the chances of misalignment between the track bearings and the track or guide rails. Misalignment can lead to uneven loading, increased friction, and accelerated wear and tear on the bearings. Proper alignment reduces these issues, ensuring smooth and efficient operation.

- Prevention of Contamination: During installation, it is important to take precautions to prevent contamination of the track bearings. Proper handling techniques, cleanliness, and the use of appropriate tools or protective measures help avoid introducing dirt, dust, or debris that can compromise the bearing’s performance and longevity.

Alignment Impact:

- Reduced Friction and Wear: Proper alignment of track bearings helps minimize friction and wear. When bearings are misaligned, excessive forces and irregular motion can occur, leading to increased friction and accelerated wear. Proper alignment ensures that the bearings operate within their intended design parameters, reducing friction and promoting longevity.

- Optimal Load Distribution: Correct alignment ensures that the load is distributed evenly across the track bearings. This prevents excessive stress on specific areas of the bearings, reducing the risk of premature failure and extending their service life. Optimal load distribution also contributes to smoother operation and improved overall performance.

- Minimized Noise and Vibration: Proper alignment helps minimize noise and vibration during operation. Misaligned track bearings can result in irregular motion, leading to unwanted noise and vibration that can affect the performance, comfort, and efficiency of the machinery or equipment. Proper alignment promotes smoother and quieter operation.

- Improved Efficiency: When track bearings are correctly aligned, the machinery or equipment experiences reduced resistance and improved efficiency. Misalignment can result in energy losses, increased power consumption, and decreased overall efficiency. Proper alignment ensures optimal power transfer and minimizes energy wastage.

It is important to follow the manufacturer’s guidelines and recommendations for the specific track bearings being installed. Proper installation techniques, including accurate positioning, secure fastening, and appropriate alignment, contribute to the optimal performance, reliability, and longevity of track bearings in various applications.

Can track bearings be used in both light-duty and heavy-duty machinery applications?

Yes, track bearings can be used in both light-duty and heavy-duty machinery applications. They are versatile components that offer reliable support for linear motion in a wide range of industrial settings. Here’s a detailed explanation:

1. Light-Duty Machinery Applications:

In light-duty machinery applications, track bearings provide cost-effective and efficient solutions for various tasks. Light-duty track bearings are designed to handle lower loads and are commonly used in applications such as:

- Office automation equipment

- Consumer electronics

- Printing machinery

- Small conveyors and material handling systems

- Automated vending machines

- Textile machinery

These applications typically involve lighter loads and lower operating speeds, making light-duty track bearings suitable for providing smooth and reliable linear motion.

2. Heavy-Duty Machinery Applications:

Track bearings are also widely used in heavy-duty machinery applications that require robust components capable of handling substantial loads and challenging operating conditions. Heavy-duty track bearings are designed to withstand higher loads and offer increased durability. They are commonly employed in applications such as:

- Material handling equipment

- Construction machinery

- Mining equipment

- Transportation systems

- Industrial automation

- Large-scale conveyors

- Steel mills

These applications often involve heavy loads, high operating speeds, and demanding environments. Track bearings in heavy-duty machinery applications are engineered to provide reliable performance, extended service life, and resistance to factors such as contamination, shock, and vibration.

Track bearings are available in various sizes, designs, and load capacities, allowing them to be tailored to the specific requirements of both light-duty and heavy-duty machinery applications. Manufacturers offer a range of options to accommodate different load capacities, operating conditions, and performance specifications.

It is important to consider the specific requirements and operating conditions of the machinery application when selecting track bearings. Consulting with bearing manufacturers or industry experts can help ensure the appropriate track bearings are chosen for optimal performance and reliability in both light-duty and heavy-duty machinery applications.

Are there specific materials commonly used in the construction of track bearings?

Yes, specific materials are commonly used in the construction of track bearings to ensure their durability, load-carrying capacity, and resistance to various operating conditions. Let’s discuss the materials commonly used for different components of track bearings:

- Outer and Inner Rings: The outer and inner rings of track bearings are typically made from high-quality bearing steels such as chrome steel (e.g., AISI 52100) or stainless steel. These materials offer excellent strength, hardness, and wear resistance. Chrome steel is the most commonly used material due to its favorable combination of mechanical properties and cost-effectiveness. In some cases, specialized alloys or heat-treated steels may be used to enhance specific properties like corrosion resistance or high-temperature performance.

- Rolling Elements: The rolling elements in track bearings are commonly made from bearing-grade steel or ceramic materials. Bearing-grade steel, similar to the materials used for the outer and inner rings, offers high strength and wear resistance. Ceramic materials, such as silicon nitride (Si3N4) or zirconia (ZrO2), are also used in certain applications where their advantages, such as high hardness, low density, and resistance to corrosion and high temperatures, are desired.

- Cage: The cage in track bearings is typically made from materials such as steel, brass, or engineered polymers. Steel cages are commonly used due to their strength and durability. Brass cages offer good corrosion resistance and are suitable for certain operating environments. Engineered polymers, such as polyamide (nylon), are used in applications where low friction, noise reduction, or lightweight design is desired.

- Seals or Shields: The seals or shields used in track bearings are made from various materials depending on the specific requirements. Common materials include rubber or synthetic elastomers for seals, and steel or stainless steel for shields. These materials provide effective protection against contaminants while maintaining proper lubrication within the bearing assembly.

- Lubrication: Lubricants used in track bearings can vary depending on the application and operating conditions. Common lubrication options include mineral oils, synthetic oils, and greases. The lubricant’s formulation is carefully chosen to provide adequate lubrication, reduce friction and wear, and protect against corrosion and contamination.

Overall, the choice of materials for track bearings is influenced by factors such as load requirements, operating conditions (including temperature and moisture levels), desired lifespan, and cost considerations. By selecting appropriate materials for each component, track bearings can deliver reliable performance and extended service life in a wide range of industrial and mechanical applications.

editor by CX 2024-02-21