Product Description

Heavy Duty Track Xihu (West Lake) Dis. Roller Bearing 7909 32005 Inch Tapered Roller Bearing

Product Description

Tapered roller bearings refer to radial thrust rolling bearings whose rolling elements are tapered rollers. There are 2 kinds of small cone angle and large cone angles. The small cone angle mainly bears the combined radial and axial loads dominated by radial loads. It is often used in pairs and installed in reverse. The inner and outer races can be installed separately, and the radial and axial clearances can be adjusted during installation and use; The large cone angle mainly bears the combined axial and radial loads, which are mainly axial loads. Generally, it is not used to bear pure axial loads alone but can be used to bear pure radial loads when arranged in pairs (the ends with the same name are installed opposite to each other).

Tapered roller bearings are separable bearings, and both the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into different structural types such as single-row, double-row, and four-row tapered roller bearings according to the number of rows of rollers installed. Single-row tapered roller bearings can bear radial loads and axial loads in 1 direction. When the bearing is subjected to radial load, an axial component force will be generated, so another bearing that can withstand the axial force in the opposite direction is needed to balance it.

Size range

The basic dimensions of CZPT tapered roller bearings are listed in the dimension data table,

Single-row tapered roller bearings:

Inner diameter size range: 20mm~1270mm

Outer diameter range: 40mm~1465mm

Width size range: 15mm~240mm

Double-row tapered roller bearings:

Inner diameter size range: 38mm~1560mm

Outer diameter range: 70mm~1800mm

Width size range: 50mm~460mm

Four-row tapered roller bearings:

Inner diameter size range: 130mm~1600mm

Outer diameter size range: 200mm~2000mm

Width size range: 150mm~1150mm

Product Parameters

|

Product Name |

Tapered Roller Bearing |

|

Type |

Tapered Roller Bearing |

|

Structure |

Tapered roller, retainer, inner and outer ring tapered |

|

Applicable Industries |

Building materials workshop, construction engineering, machinery maintenance workshop, retail, manufacturing plant, motor, |

|

Brand Name |

HOTE BEARING |

|

Size |

20mm-500mm |

|

Accuracy Class |

P6,P0,P4,P5 |

|

Seal Number of Rows |

Single row / Double row / Four-row |

|

Origin |

ZheJiang , China |

|

Material |

GCr15 |

|

Service |

OEM / ODM |

|

Features |

Long-life High Speed |

| Bearing No. | Dimension(mm) | Basic Load | Weight(kg) | |||||

| Model No. | d | D | T | B | C | r(min) | r1(min) | |

| 3980/3920 | 60.325 | 112.712 | 30.162 | 30.048 | 23.812 | 3.5 | 3.3 | 1.29 |

| 558/552 | 60.325 | 123.825 | 38.1 | 36.678 | 33.338 | 2.3 | 3.3 | 2.12 |

| 28985/28921 | 60.325 | 100 | 25.4 | 25.4 | 19.845 | 3.5 | 3.3 | |

| 28598/28920 | 60.325 | 101.6 | 25.4 | 25.4 | 19.845 | 3.5 | 3.3 | 79 |

| 390A/394AS | 63.5 | 110 | 22 | 21.996 | 18.821 | 1.5 | 3.3 | 0.82 |

| L610549/61571 | 63.5 | 94.458 | 19.05 | 19.05 | 15.083 | 1.5 | 1.5 | 0.45 |

| 3982/3920 | 63.5 | 112.712 | 30.162 | 30.048 | 2.812 | 3.5 | 3.3 | 1.22 |

| HM212047/HM212011 | 63.5 | 12.238 | 38.1 | 38.354 | 29.718 | 7 | 3.3 | 1.91 |

| 559/552A | 63.5 | 123.825 | 38.1 | 36.678 | 30.163 | 2.5 | 2.3 | 1.93 |

| 29585/29520 | 63.5 | 107.85 | 25.4 | 25.4 | 19.05 | 3.5 | 3.3 | 0.91 |

| 29585/29521 | 63.5 | 110 | 25.4 | 25.4 | 19.05 | 4 | 1.3 | 0.98 |

| JM511946/JM511910 | 65 | 110 | 28 | 28 | 22.5 | 3 | 2.5 | 1.05 |

| JLM710949/JLM71571 | 65 | 102 | 24 | 23 | 28.5 | 3 | 13.3 | 0.72 |

| HM212049/HM212011 | 66.675 | 122.238 | 38.1 | 38.354 | 29.718 | 3.5 | 1.3 | 1.384 |

| 395A394A | 66.675 | 110 | 22 | 21.996 | 18.824 | 0.8 | 1.3 | 1.06 |

| 395S/394A | 66.675 | 110 | 22 | 21.996 | 18.824 | 3.5 | 3.3 | 0.78 |

| 29590/29520 | 66.675 | 107.95 | 25.4 | 25.4 | 19.05 | 3.5 | 0.8 | 0.84 |

| 29590/29522 | 66.675 | 107.95 | 25.4 | 25.4 | 19.05 | 3.6 | 3.3 | 0.864 |

| 39590/39520 | 66.675 | 112.712 | 30.162 | 30.62 | 23.812 | 3.5 | 3.3 | 1.13 |

| 3984/3920 | 66.675 | 112.712 | 30.162 | 30.048 | 23.812 | 3.5 | 3.3 | 0.78 |

| 3994/3920 | 66.675 | 112.712 | 30.162 | 30.048 | 23.812 | 5.5 | 1.3 | 1.15 |

| 399A/394A | 68.262 | 110 | 22 | 21.996 | 18.824 | 2.3 | 1.3 | 0.74 |

| 560S/552A | 68.262 | 123.825 | 38.1 | 36.678 | 30.162 | 3.5 | 2 | 1.84 |

| 482/472 | 69.85 | 120 | 29.795 | 29.007 | 24.237 | 3.5 | 3.3 | 1.25 |

| 33275/33462 | 69.85 | 117.475 | 30.162 | 30.162 | 23.812 | 3.5 | 0.8 | 1.25 |

| 33275/33472 | 69.85 | 120 | 29.794 | 30.163 | 23.444 | 3.6 | 3.3 | 1.25 |

| H913849/H9138710 | 69.85 | 146.05 | 41.275 | 39.688 | 25.4 | 3.5 | 3.3 | 2.85 |

| 47487/47420 | 59.85 | 120 | 32.545 | 32.525 | 26.195 | 3.5 | 3.3 | 1.46 |

| 47487/47420X | 69.85 | 120 | 32.545 | 32.525 | 26.915 | 3.2 | 2.5 | 1.46 |

| JM612949/JM612910 | 70 | 115 | 29 | 29 | 23 | 3 | 2.5 | 1.13 |

| JLM813049/JLM813571 | 70 | 110 | 26 | 25 | 20.51 | 1 | 2 | 0.88 |

| 567/563 | 73.571 | 127 | 36.512 | 30.17 | 28.575 | 3.5 | 3.3 | 1.79 |

| 29685/29620 | 73.571 | 112.712 | 25.4 | 25.4 | 19.05 | 3.5 | 3.3 | 0.88 |

| 33287/33462 | 73.571 | 117.475 | 30.162 | 30.162 | 23.812 | 3.5 | 0.8 | 1.17 |

| 33287/33472 | 73.571 | 120 | 2.794 | 30.162 | 23.444 | 3.5 | 3.3 | 1.26 |

| 575/572 | 76.2 | 139.992 | 36.512 | 36.098 | 28.575 | 3.5 | 3.3 | 2.37 |

| K495A/493 | 76.2 | 136.525 | 30.162 | 27.769 | 22.225 | 3.6 | 3.3 | 1.8 |

| 755/752 | 76.2 | 161.925 | 47.625 | 48.26 | 38.1 | 3.5 | 3.3 | 4.68 |

| 9285/9220 | 76.2 | 161.925 | 49.212 | 40.038 | 31.75 | 3.5 | 3.3 | 4.24 |

| 9378/9320 | 76.2 | 117.8 | 52.387 | 50.8 | 34.925 | 3.5 | 3.3 | 6.05 |

| 42687/42620 | 76.2 | 127.8 | 30.162 | 31 | 22.225 | 3.5 | 3.3 | 1.45 |

| HH221430/HH221410 | 76.2 | 19.5 | 57.15 | 57.531 | 46.038 | 3.5 | 3.3 | 8.86 |

| JM515649/JM515610 | 80 | 130 | 35 | 34 | 28.5 | 3 | 2.5 | 1.7 |

| 740/742 | 80.962 | 150.089 | 44.45 | 46.672 | 36.512 | 5 | 3.3 | 3.39 |

| 495/493 | 82.55 | 136.525 | 30.162 | 29.769 | 22.225 | 3.5 | 3.3 | 1.6 |

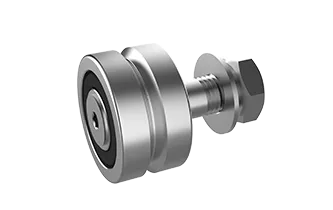

Detailed Photos

FAQ

Q1:What is your Before-sales Service?

1>. Offer to bear related consultation about technology and application;

2>.Help customers with bearing choice, clearance configuration, product” life, and reliability analysis;

3>. Offer highly cost-effective and complete solution program according to site conditions;

4>. Offer localized program on introduced equipment to save running cost

Q2: What is your After-sales Service?

1>. Offer training about bearing installation and maintenance;

2>.Help customers with trouble diagnosis and failure analysis;

3>. Visit customers regularly and feedback on their rational suggestions and requirements to the company.

Q3: How about your company’s strength?

1>.FREE SAMPLES:

contact us by email or trade manager, we will send the free samples according to your request.

2>. World-Class Bearing:

We provide our customers with all types of indigenous roller bearings of world-class quality.

3>.OEM or Non-Stand Bearings:

Any requirement for Non-standard roller bearings is Easily Fulfilled by us due to our vast knowledge and links in the industry.

4>.Genuine products With Excellent Quality:

The company has always proved the 100% quality products it provides with genuine intent.

5>. After-Sales Service and Technical Assistance:

The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

6>.Quick Delivery:

The company provides just-in-time delivery with its streamlined supply chain.

7>.Cost Saving:

We provide long-life, shock-resistant, and high-reliability roller bearings with excellent quality and better performance.

Resulting in increased cost savings.

Q4: What will we do if you are not satisfied with the product?

A: If have any abnormal, Please contact us at the first time, and we will immediately process

Q5: How long will you respond to our problems?

A: We will respond within 1 hour. 24 hours to solve your problem

Q6: Is optional lubrication provided?

A: We can offer a wide range of oils and greases for a variety of applications. Please contact our engineer for technical

assistance with any special requirements

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Multi-column |

| Outer Dimension: | Small (28-55mm) |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can track bearings be customized or modified for specific track or linear motion applications?

Yes, track bearings can be customized or modified to meet specific requirements of track or linear motion applications. Manufacturers often offer a range of options and capabilities to tailor track bearings to the unique needs of different industries and applications. Here are some ways in which track bearings can be customized or modified:

- Size and Dimensional Variations: Track bearings can be customized in terms of size, diameter, width, and overall dimensions to fit specific track or linear motion systems. Manufacturers can provide bearings with varying sizes and load capacities to accommodate different application requirements.

- Material Selection: Track bearings can be manufactured from various materials depending on the specific application’s demands. Common materials include steel, stainless steel, ceramic, and polymer composites. Material selection can be customized to achieve desired properties such as corrosion resistance, high temperature tolerance, or low friction.

- Sealing and Protection: In applications where track bearings are exposed to contaminants, moisture, or harsh environments, customized sealing and protection features can be added. These may include additional seals, shields, or coatings to enhance the bearing’s resistance to dust, water, chemicals, or extreme temperatures.

- Lubrication Options: While self-lubricating or maintenance-free track bearings offer convenience, applications with specific lubrication requirements may benefit from customized lubrication options. Manufacturers can modify the bearing design to accommodate external lubrication systems or provide alternative lubrication methods to meet the unique demands of the application.

- Specialized Load and Speed Ratings: In certain applications, track bearings may need to handle exceptionally high loads or operate at high speeds. Manufacturers can customize the bearing design to offer specialized load and speed ratings to ensure optimal performance and reliability in such demanding conditions.

- Mounting and Attachment Options: Track bearings can be customized with different mounting and attachment options to facilitate easy installation and integration into specific track or linear motion systems. This may include variations in bolt hole patterns, flange designs, or specialized mounting arrangements.

- Track Geometry Compatibility: Track bearings can be designed or modified to match specific track or guide rail geometries. This ensures proper fit, alignment, and smooth operation along the designated track, minimizing the risk of misalignment or issues related to track compatibility.

It is important to work closely with bearing manufacturers or suppliers to discuss the specific requirements of the track or linear motion application. By collaborating with experts, it is possible to customize or modify track bearings to optimize performance, reliability, and longevity in a wide range of applications.

Can track bearings withstand harsh environments or exposure to contaminants?

Track bearings are designed to operate in a wide range of environments, including harsh conditions and exposure to contaminants. However, the ability of track bearings to withstand such environments depends on their specific design, materials, and protective measures. Here’s a detailed explanation:

Many track bearings are engineered with features that enhance their resistance to harsh environments and contaminants. These features may include:

- Sealing and Shielding: Some track bearings are equipped with seals or shields that provide a physical barrier against contaminants such as dirt, dust, water, and debris. These seals or shields help prevent the entry of contaminants into the bearing’s internal components, reducing the risk of damage and premature wear.

- Corrosion Resistance: Track bearings intended for use in corrosive environments are often constructed from materials that offer high corrosion resistance. Stainless steel, for example, is commonly used due to its ability to withstand exposure to moisture, chemicals, and other corrosive substances.

- Specialized Coatings: Some track bearings may feature specialized coatings or surface treatments that provide additional protection against contaminants and harsh conditions. These coatings can enhance the bearing’s resistance to corrosion, abrasion, and chemical exposure.

- High-Temperature Capability: Certain track bearings are designed to withstand high-temperature environments. They are typically constructed using heat-resistant materials and lubricants that can maintain their structural integrity and performance even under extreme heat.

- Environmental Sealing: In applications where track bearings are exposed to extreme conditions, such as underwater or in highly dusty environments, special environmental sealing measures may be employed. These measures can include the use of advanced sealing technologies or the encapsulation of the bearings within protective housings.

While track bearings are designed to withstand harsh environments and exposure to contaminants, it is important to note that their performance and longevity can still be affected over time. Regular maintenance, including cleaning, inspection, and lubrication, is crucial to ensure proper functioning and to mitigate the impact of contaminants on the bearings.

It is recommended to consult the manufacturer’s specifications and guidelines for the track bearings being used in a specific application. Manufacturers often provide information on the environmental ratings and limits of their bearings, helping users determine the suitability of the bearings for particular harsh environments or exposure to contaminants.

By selecting track bearings with appropriate features, materials, and protection, and by implementing proper maintenance practices, it is possible to enhance the bearings’ ability to withstand harsh environments and exposure to contaminants, thereby maximizing their performance and longevity.

How do track bearings compare to other types of bearings like ball bearings or roller bearings?

Track bearings, ball bearings, and roller bearings are all types of rolling bearings used in various applications. Let’s compare track bearings to ball bearings and roller bearings to understand their similarities and differences:

- Design and Construction: Track bearings, ball bearings, and roller bearings have different designs and constructions. Track bearings, also known as track rollers or track follower bearings, are designed specifically for guided linear or rotational motion along a track or guide rail. They feature an outer ring with a track surface, an inner ring, rolling elements (such as rollers or needles), and a cage. Ball bearings, on the other hand, have spherical rolling elements (balls) sandwiched between inner and outer rings. Roller bearings, as the name suggests, have cylindrical or tapered rolling elements (rollers) between inner and outer rings.

- Motion and Load Handling: Track bearings are primarily used for guided motion in track-based systems, while ball bearings and roller bearings are used for general rotational or linear motion. Track bearings are designed to support both radial and axial loads and provide smooth and controlled motion along the track. Ball bearings and roller bearings are also capable of supporting radial and axial loads but are typically used in applications where the motion is not constrained to a specific track or guide rail. Roller bearings, with their larger contact area and higher load-carrying capacity, are often preferred for applications with higher loads.

- Applications: Track bearings are commonly used in applications such as material handling systems, conveyors, cam mechanisms, automated machinery, construction equipment, and agricultural machinery, where guided motion along a track or rail is required. Ball bearings and roller bearings find applications in a wide range of industries and systems, including electric motors, pumps, automotive applications, industrial machinery, and appliances.

- Friction and Efficiency: Track bearings, ball bearings, and roller bearings all aim to minimize friction and ensure efficient operation. However, due to their different designs and contact surfaces, they exhibit varying levels of friction. Ball bearings typically have lower friction due to point contact between the balls and the raceways. Roller bearings, especially tapered roller bearings, distribute the load over a larger contact area, resulting in slightly higher friction compared to ball bearings. Track bearings, with their track interface, may have slightly higher friction compared to ball bearings or roller bearings due to the rolling elements’ contact with the track surface.

- Installation and Maintenance: Track bearings, ball bearings, and roller bearings require proper installation and maintenance for optimal performance and longevity. However, track bearings may require additional attention during installation as they need to be properly aligned with the track or guide rail. Regular lubrication and periodic inspection are essential for all types of bearings to ensure smooth operation and prevent premature failure.

In summary, track bearings, ball bearings, and roller bearings have distinct designs and applications. Track bearings are specialized for guided motion along a track or rail, while ball bearings and roller bearings are more versatile and used in a wide range of rotational or linear motion applications. Each type of bearing has its advantages and considerations in terms of load handling, friction, efficiency, and installation requirements. Selecting the appropriate bearing type depends on the specific application requirements, load conditions, motion characteristics, and environmental factors.

editor by CX 2024-04-17