Product Description

Needle Roller Bearing

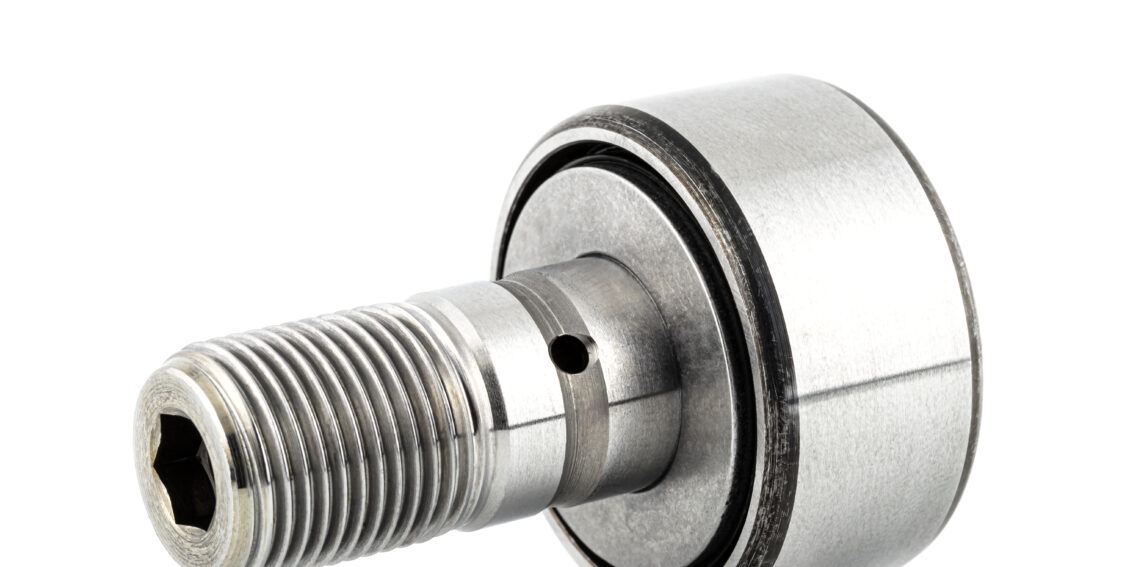

20mm Drawn Cup Needle Roller Bearing HK2016 HK2571

Needle roller bearings (needle bearing) is a cylindrical roller with a roller bearing, relative to its diameter, roller both thin and long. This is called needle roller. Despite having a smaller cross-section, has a higher load bearing capacity, equipped with a thin and long needle bearing roller (roller diameter D2.5, L is the length of the roller), therefore radial structure is compact, its diameter size and load capacity and other types of bearings, minimum diameter, especially for radial mounting dimensions restricted support structure.

According to different occasions, can be used without inner ring of the bearing or needle roller and cage assembly, when the surface of the journal bearing surface and shell holes as bearing directly match the outer rolling surface, in order to ensure the load capacity and operating performance and have the same ring bearing, shaft or housing bore raceway surface hardness, machining accuracy and surface quality should be similar roller bearing rings. Such bearings can only bear radial load.

Application:

Needle roller bearings are widely used in cars, compressors, construction, electric motors, food industry, home appliances etc. As a rolling element, it turns the world.

Product Description

|

P/N |

Drawn Cup Needle Roller Bearing HK384825 TA 3825 Size 38*48*25mm for baw BAW |

||

|

Precision |

ABEC-1 |

||

|

Type |

Needle Roller Bearings |

||

|

Lubrication |

Oil |

||

|

Material |

Chrome Steel |

||

|

Package |

Plastic Bag and Box |

||

|

Payment Item |

T/T ,Western Union , Paypal ,Credit card |

||

|

Delivery time |

3-10day |

||

1.Bearing Specifications :

Needle roller bearings use long, thin cylindrical rollers to support radial loads. These needle rollers have a length that is

typically 3 to 4 times its diameter. Needle roller bearings have a thinner cross section than other roller bearings and are ideal for limited-space applications that require carrying heavy loads. Drawn cup needle roller bearings have a deeply drawn, thin-walled outer ring. Caged drawn cup units contain a one-piece cage to CZPT and retain the rollers. Full-complement drawn cup units include the maximum number of rollers that can be retained by the outer shell. The drawn design allows for cost-effective accommodation of heavy radial loads. Needle roller and cage assemblies do not contain inner or outer rings. Instead, the self-contained bearing components work with a shaft or housing bore used as a raceway.

Product Parameters

Our Advantages

Advantages of needle roller bearings

Needle roller bearings are equipped with thin and long rollers. Therefore, the radial structure is compact.

When the inner diameter and load capacity are the same as other types of bearings, the outer diameter is the smallest. It is especially suitable for the support structure with limited radial installation size.

Needle roller bearings should be combined with bearing rings and applications depending on the application occasions, machining accuracy and surface quality

Features

3.CROWNTRANS Bearing Features :

Lower cross-section height and higher load capacity than traditional ball bearings.

Small and compact for reduced overall machine size in light weighting efforts.

Widely used in automobiles, motorcycles, printing presses, industrial robots, construction equipment and other demanding

applications.

Many styles to choose from including: radial, thrust and combined models, cam followers and roller followers..

Product Application

2.Application of Bearing :

1.Needle roller bearing: used in automobile engine, transmission, crawler wheel of excavator, compressor, crane, etc.2.Combined needle roller bearing is widely used in machine tools, metallurgical machinery, textile machinery, printing machinery and other mechanical equipment, and can make the mechanical system design very compact and smart.

Company Profile

Packaging & Shipping

II.PACKAGING & SHIPPING

1) Inner Plastic Bag+ Paper Box + Carton(+Pallet);

2) Small sizes:Plastic Tube + Carton

3) Big sizes:Wooden Case

1)Less than 45 KGS, we will send by express. (Door to Door, Convenient)

2)Between 45 – 200 KGS, we will send by air transport. (Fastest and safest, but ?expensive )

3)More than 200 KGS, we will send by sea. (Cheapest and usual)

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.We have our own brand:.If you interested in our product,I can take you to visit our factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in ZheJiang Province,You can take the high-speed rail or plane to visit.

Q: Do you provide samples ? it is free charge?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q:The MOQ is how much?

A: About ordinary standard type of bearing ,We have rich inventory,not have MOQ,if your need a

product is Non-standard size,need customize,we will according the product size to determine the MOQ.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Cage: | Without Cage |

|---|---|

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Style: | With Inner Ring |

| Material: | Bearing Steel |

| Type: | Open |

| Samples: |

US$ 0.01/Set

1 Set(Min.Order) | |

|---|

How does proper installation and alignment impact the performance and longevity of track bearings?

Proper installation and alignment play a critical role in the performance and longevity of track bearings. Correct installation ensures that the bearings are positioned and secured accurately, while proper alignment ensures that the load is distributed evenly and the bearings operate smoothly. Here’s an explanation of how proper installation and alignment impact the performance and longevity of track bearings:

Installation Impact:

- Load Distribution: Proper installation ensures that the track bearings are aligned and positioned correctly, allowing for even load distribution. When bearings are installed incorrectly, the load may be unevenly distributed, leading to excessive wear on certain parts of the bearings and reduced overall performance.

- Stability and Rigidity: Accurate installation provides stability and rigidity to the track bearings. Properly secured bearings minimize the risk of movement or vibration during operation, which can cause additional stress, premature wear, and potential damage to the bearings and surrounding components.

- Reduction of Misalignment: Correct installation minimizes the chances of misalignment between the track bearings and the track or guide rails. Misalignment can lead to uneven loading, increased friction, and accelerated wear and tear on the bearings. Proper alignment reduces these issues, ensuring smooth and efficient operation.

- Prevention of Contamination: During installation, it is important to take precautions to prevent contamination of the track bearings. Proper handling techniques, cleanliness, and the use of appropriate tools or protective measures help avoid introducing dirt, dust, or debris that can compromise the bearing’s performance and longevity.

Alignment Impact:

- Reduced Friction and Wear: Proper alignment of track bearings helps minimize friction and wear. When bearings are misaligned, excessive forces and irregular motion can occur, leading to increased friction and accelerated wear. Proper alignment ensures that the bearings operate within their intended design parameters, reducing friction and promoting longevity.

- Optimal Load Distribution: Correct alignment ensures that the load is distributed evenly across the track bearings. This prevents excessive stress on specific areas of the bearings, reducing the risk of premature failure and extending their service life. Optimal load distribution also contributes to smoother operation and improved overall performance.

- Minimized Noise and Vibration: Proper alignment helps minimize noise and vibration during operation. Misaligned track bearings can result in irregular motion, leading to unwanted noise and vibration that can affect the performance, comfort, and efficiency of the machinery or equipment. Proper alignment promotes smoother and quieter operation.

- Improved Efficiency: When track bearings are correctly aligned, the machinery or equipment experiences reduced resistance and improved efficiency. Misalignment can result in energy losses, increased power consumption, and decreased overall efficiency. Proper alignment ensures optimal power transfer and minimizes energy wastage.

It is important to follow the manufacturer’s guidelines and recommendations for the specific track bearings being installed. Proper installation techniques, including accurate positioning, secure fastening, and appropriate alignment, contribute to the optimal performance, reliability, and longevity of track bearings in various applications.

What innovations or advancements have been made in track bearing technology?

Track bearing technology has seen several innovations and advancements over the years, driven by the need for improved performance, increased reliability, and enhanced functionality. Here are some notable innovations in track bearing technology:

- Advanced Materials: The development of new materials has significantly improved the performance and longevity of track bearings. Materials such as ceramic, hybrid ceramics, and high-performance steels offer enhanced strength, corrosion resistance, and temperature stability, making them suitable for demanding applications.

- Improved Sealing Solutions: Sealing technology has advanced to provide better protection against contaminants, moisture, and other environmental factors. Innovative seal designs and materials, including labyrinth seals, triple lip seals, and specialized coatings, help keep track bearings clean and extend their service life.

- Enhanced Lubrication: Lubrication plays a crucial role in the performance and lifespan of track bearings. Advancements in lubrication technology, such as the development of high-performance greases and solid lubricants, have improved the efficiency, reliability, and maintenance requirements of track bearings.

- Integrated Sensor Systems: Track bearings can now incorporate integrated sensor systems to monitor various parameters such as temperature, vibration, and load. These sensors provide real-time data on bearing health and performance, enabling predictive maintenance strategies and early detection of potential issues.

- Smart Bearing Technology: Smart bearing technology combines sensor systems with advanced data analytics and connectivity capabilities. These bearings can communicate wirelessly with monitoring systems, enabling remote monitoring, condition-based maintenance, and optimization of operational parameters for improved performance and efficiency.

- Design Optimization: Computer-aided design (CAD) and finite element analysis (FEA) tools have revolutionized the design process for track bearings. These tools allow for precise modeling, simulation, and optimization of bearing geometries, materials, and load capacities, resulting in improved performance, reduced weight, and enhanced reliability.

- Application-Specific Customization: With advancements in manufacturing processes, track bearings can now be customized to meet the specific requirements of different applications. Manufacturers can tailor bearing designs, materials, and coatings to optimize performance, reliability, and compatibility with unique operating conditions.

These innovations and advancements in track bearing technology have collectively contributed to improved performance, extended service life, and enhanced functionality in a wide range of industries and applications. They continue to drive progress in the field, enabling track bearings to meet the evolving demands of modern industrial systems.

How do track bearings contribute to smooth and precise motion in machinery and equipment?

Track bearings play a crucial role in enabling smooth and precise motion in machinery and equipment. They provide support and guidance for moving components, allowing them to move along tracks or guide rails with minimal friction and accurate positioning. Let’s explore how track bearings contribute to smooth and precise motion:

- Reduced Friction: Track bearings are designed to minimize friction between the rolling elements (such as balls or rollers) and the raceways (inner and outer rings). By reducing friction, track bearings help to minimize energy losses, prevent excessive heat generation, and extend the lifespan of the bearing and other components in the system. Low friction enables smoother and more efficient motion, resulting in improved overall performance.

- Accuracy and Precision: Track bearings are manufactured to precise tolerances, ensuring consistent dimensions and smooth surfaces. This precision contributes to accurate and repeatable positioning of the moving components along the track or guide rail. It allows machinery and equipment to achieve the desired motion with minimal deviation or backlash, enabling precise control and operation.

- Load Distribution: Track bearings are designed to distribute loads evenly across the rolling elements and raceways. This load distribution helps prevent localized stress concentrations and ensures that the applied loads are shared by multiple contact points. By distributing the loads effectively, track bearings enhance the stability and integrity of the moving components, reducing the risk of premature wear or failure.

- Guidance and Alignment: Track bearings provide guidance and alignment for the moving components. They help maintain the desired orientation and position of the components along the track or guide rail, preventing misalignment and unwanted movements. This guidance ensures smooth and precise motion, minimizing vibrations, noise, and the risk of component damage or malfunction.

- Shock and Impact Absorption: Track bearings are designed to absorb shocks and impacts that may occur during operation. They help cushion the effects of sudden loads or vibrations, protecting the moving components and reducing the transmission of these forces to the rest of the machinery or equipment. This shock absorption capability contributes to smoother and more stable motion, enhancing overall performance and reliability.

By incorporating high-quality track bearings into machinery and equipment, engineers can achieve smooth and precise motion, improving the efficiency, accuracy, and longevity of the system. Proper selection, installation, and maintenance of track bearings are essential to ensure optimal performance and to minimize the risk of issues such as excessive wear, misalignment, or loss of motion control.

editor by CX 2024-04-12