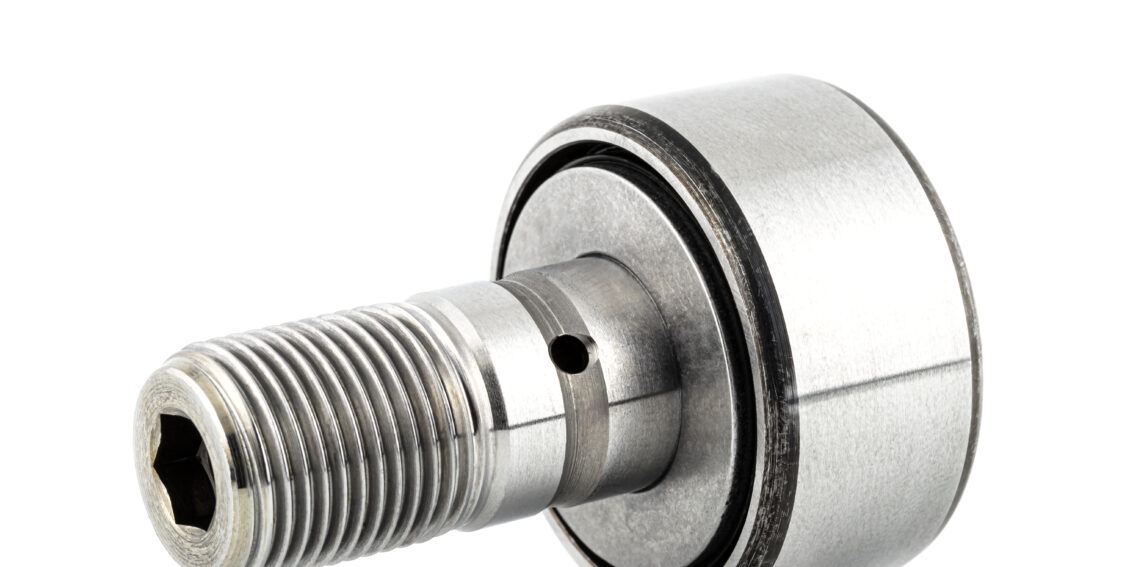

Product Description

KR30PP CF12BUUR stud type cam follower track roller bearing germany

Quick Details

Precision Rating: P0, P4, P5, P6

Seals Type: SEALED

Number of Row: Single Row

Application: Machine tool, reducer, textile, packing, office automation, metallurgy

Rolling: Needle

Lubrication: Oil, greese

Structurer: Cage, outer ring, inner ring, needle

OEM service: Accept

Material: Chrome steel, carbon steel, stainless steel

Sample: Offered

Full complement needle roller bearing

High precision

China manufacturer

Packaging & Delivery

Packaging Detail: Track roller bearing packing:

1. Industrial packaging: Plastic bag + kraft paper + carton + plywood pallets; Plastic tube + carton + plywood pallets; 2. Commercial packing: 1PC/plastic bag + color box + carton + plywood pallets 3. As the customers’ requirement

Delivery Detail: 4-45 Working Daysk

HF0406

HFZ121610

HF0612

HFL0408

HF571

HFL0615

HF1012

HFL0822

HF1216

HFL1571

HF1416

HFL1226

HF1612

HFL1426

HF1816

HFL1626

HF2016

HFL1826

HF2520

HFL2026

HF3571

HFL2530

HF3520

HFL3030

HFZ040708

HFL3530

HFZ061008

HFLZ061014

HFZ57108

HFLZ57114

HFZ101410

HFLZ101416

KH0622

KH2030

KH0824

KH2540

KH1026

KH3050

KH1228

KH4060

KH1428

KH5070

KH1630

SCE34

SN1812

SCE65

SN2016

SCH88

SN3216

SCE108

FY182416

SCE148

FY257130

SCE228

FY222816

SCE1212

SCE1314

SCE1412

SCE1612

SCE1616

SCE1816

SCE2420

SCE2620

SCE2810

SCE2812

SCE2816

SCE3228

HK0408

HK2571

HK0608

HK2571(ASI)

HK0610

TA2571

HK0609

HK2016(ASI)

HK0808(ASI)

HK25712

HK571

HK257110

HK1571

HK257118(RS)

HK1012

HK2110

HK111512

HK222810

HK1210

HK2512(ASI)

HK1212(ASI)

HK2520(ASI)

HK13.5 12

HK2216(ASI RS)

HK1412

HK2218(ASI RS)

HK1512

HK1616(2RS)

HK1515

HK2220(2RS)

HK1516(ASI)

HK253315

HK1522(ASI)

HK2830

HK1612

HK283520

BHA1612(ASI)

HK3516

BHA1616(ASI)

HK3520

HK1616(ASI)

HK354224

HK172518(RS)

HK4571

HK1812

HK4520

HK1825

HK4538

K 0571 1

K101314.5

K 0571 1

K101316

K060907

K101323EW

K06 0571

K10.319×13.494×12.7

K06571

K101408

K06571

K101409

K06571

K101410

K06571

K101411

K061571

K101412

K57108

K101413Kw

K 0571 71

K101415

K081108

K101420EW

K081109

K101424EW

K081110

K101610

K081112

K101612

K081112.5

K111410

K081113

K111413

K57108

K111510.5

K57109

K111512.5

K57110

K111517

K57112

K121510

K57116

K121513

K57110

K121514

K57111.8

K121515

K57112

K121516

K57113

K121516.5

K57116

K121517

K57112

K121517.5

K57113

K121608

K9.525×12.525×9.7

K121610

K101310

K121612

K101312

K121613

K101313

K121614

K101314

K121615

K141418.8

K121615 O

K141819

K121616

K141820

K121616.5

K141910

K121620

K141911.8

K121622

K141912

K121624EW

K141913

K121710

K141917

K121713

K141918

K121714

K141920

K121715

K142012

K121720.5

K142013

K121810

K142015

K121812

K142030

K12.7×15.875×12.7

K142216

K131613

K14.29×17.46×15.88

K131614

K151816

K131714

K151816.5

K131810

K151817

K131811

K151818

K131815

K151820

K141710

K151821

K141713

K151821.8

K141717

K151822

K141807

K151908

K141808

K151910

K141810

K151913

K141812

K151917

K141813

K151914

K141813

K151918

K141814

K151918.8

K141814.5

K151919

K141815

K151920

K141816.5

KK151922

K14817

K152571

K141817

K152012

K141818

K152013

K152571

K162320

K152571

K162420

K152115

K16.7×22.7×21.5

K152117

K172571

K152121

K172571.5

K152212

K172110

K15.88×19.05×12.7

K172113

K162571

K172115

K162012

K172116

K162013

K172117

K162015.8

K172120

K162016

K1721.526

K162017

K172213

K162018

K172215

K162019.5

K172216

K162571

K172220

K162571

K172223

K162571.8

K172312.6

K162571

K172315

K162110AG

K172317

WJ162112

K172318

K162114

K17.5×22×15.8

K162116

K17.5×22×16

K162119.5

K17.46×20.6×15.88

K162120

K182208

K162121.7

K182210

K162126

K182212

K162210

K182213

K162212

K182216

K162213

K182217

K162216

K182220

K162217

K182222

K162220

K182224

K162221

K182320

K162232

K182410

K162313.8

K182411.6

K182411.8

K257130

K182412

K257134

K182413

K257138.5

K182413.3

K202612

K182417

K202613

K182420

K202614

K182425

K202615

K182511.8

K202616

K182512

K202617

K182620

K202620

K182815.8

K257116

K182816

K257113

K192313

K257114

K192515

K257115

K192516

K257116

K192520

K257117

K192523

K257119.8

K192531.5

K257120

K192532

K257123

K192928

K257125

K19×25.4×25.4

K203016

WJ121616

K25711

K257108

K203030

K257110

K212517

K257111

K213927

K257112

K21.1×26.1×14

K257113

K222608

K257116

K222610

K257117

K222611

K257120

K222613

K257110

K222616

K257113

K222617

K257115

K222620

K257116

K222626

K257117

K222713

K257123

K222716

K257124

K222815

K257127

K222816

K257128

K222817

K222822.8

K253013

K222823

K253015

K222830

K253016

K222912

K253016.5

K222915.5

K253017

K222916

K253571

K223014

K253571

K223015

K253571

K223016

K253026

K223571

K253026.5

K223224

K253571

K223245

K253030

K225321

K253032

K232821.5

K253034

K232822

K25×30.5×20

K23.1×28.1×14AG

K253113

K233014

K253114

K233224

K253116

K23.3×32.3×16

K253117

K23×33×19.8

K253120

K233320

K253121

K242810

K253216

K242813

K253318

K282816

K253319

K242817

WJ162116

K242913

K253320

K243017

K253324

K243031

K253325

K243240

K253329

K243326.6

K253331.3

K243629

K253331.5

K24.8×30.8×18

K253332

K252910

K253417.5

K252913

K253417.8

K252917

K253418.8

K252920

K253422

K252930

K253515

K253516

K283420

K253518

WJ283424

K253520

K283516

K253524

K283518

K253525

K283520

K253530

K283528

K253920

K283616

K25.1×30.1×14AG

K283617

K25.4×33.34×25.4

K283620

K203008

K283646

K263571

WJ283816.6

K263012

K283817

K263013

K283825

K263017

K284030

K263114

K284040

K263125

WJ283416

K263326.6

WJ283412

K26333.3

K293523

K263334

K293817

K263418

K303429

K263432

K303434

K263525

K35716

K263825

K35717

K273227

K35710

K273618

K35710.5

K273621

K35714

K283212

K35716

K283217

K25717

K383220

K35710

K283229

K35714

K283230

K303611.8

K283313

K303613

K283314

K303613.8

K283317

K303616

K283326.6

K35716

K283327

K35718

K35710

K324242

K35710

K333920

K303815.5

K344238

K303816

K344440

K303817

K344616

K303818

K344624.5

K303820

K353934

K303824

K354013

K3 0571 7

K354016

K3571

K354016.5

K3 0571 1

K354017

K35711

K354571

K304030

K354571.5

K304222.5

K354571

K304232

K354571

K304236

K354030EW

K35715

K354031

K304430

K354033

K306026

K354034

K314530

K354040

K202616

K354114

K323625

K354135

K323713

K354140

K323717

K354216

K323720

K354220

K323727

K354230

K323730

K354236

K323816

K354324.5

K323820

K354325

K323822

K354350

K323826

K354520

K323916

K354525

K323930

K354530

K324571

K354540

K324571

K354546

K324030

K354549

K324036

K355039.5

K35×50.6×30.5

WJ243571

K364120

WJ243571

K364130

K385327.5

K364131

K394443

K364525

K394444

K364621

K394620

K364625

K395522.5

K364631

K40×44×34.6

K364722

K45713

K364825

K45717

K364830

K45710

K364571

K45711

K364031

K45716

K374217

K45716

K374222

K45719

K374224.5

K4 0571 0

K374227

K4 0571 7

K374229.8

K4 0571 9

K374230

K4571

K375227.5

K45717

K384108

K45710

K384109

K45710

K384208

K4571

K384317

K4 0571 0

K384322

K4 0571 2

K384320

K4 0571 4

K384327

K4 0571 5

K384330

K4 0571 7

K384425

K404840

K384433

K4 0571 4

K384436

K406040

K384443

K424717

K384516

K424720

K384620

K424727

K384632

K424730

K384825

K424734

K384830

K424737

K385571

K424824

K385248

K425571

K425230

K425831

K475230

K425225

K475746

K434817

K485317

K434827

K485323

K434830

K485823.3

K434831

K485328

K434833

K485329

K434839

K485425

K434931

K485429

K434932

K485439

K445039

K485517

KT44.45×53.98×25.4

K485846

K455013

K486030

K455017

K48.22×61.85×39.6

K455571

K55710

K455571

K55717

K455571

K55710

K455030

K55715

K455035

K55716

K455136

K55717

K455212

K55710

K455218

K55716

K455220

K505820

K455222

K505825

K455240

K505830

K455320

K505835

K455321

K506031

K455325

K525710

K455328

K536571.8

K454931

K546030.8

K455922

K546037

K455936

K555913

K456922

K556017

K455520

K556017

K465237

K556571.8

K465922

K556571

K475217

K556571

K475227

K556571.3

K556031

K606825

K556031.3

K606830

K556037

K606835

K556117

K606845

K556120

K606820

K556134

K616620

K556218

K626640EW

K556225

K627037EW

K556240

K627040EW

K556254

K647219.5

K556315

K647220

K556320

K657571

K556322

K657030

K556325

K657333EW

K556330

K657335

K556332

K657225

K556345

K657346EW

K556520

K657245

K556525

K657420

K556536

K687428

K566133.4

K687638.8EW

K576343

K687647.8EW

K586317

K707650EW

K586320

K707818

K586325

K707820

K586330

K707830

K586333

K707837EW

K586518

K707856EW

K586536

K7 0571 1

K586537.5

K708030

K606520

K708035

K606523

K708043EW

K606530

K707054

K6 0571 2.8

K708820

K6 0571 3

K728571

K6 0571 3

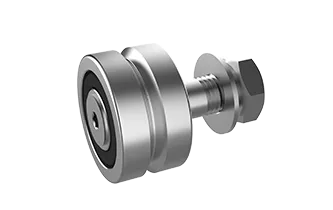

Track Roller Bearing/ yoke track roller /needle roller bearing

NATV series yoke type track roller is basically the same as NATR series. The only different is that NATV is full complement needle roller type. Therefore it can sustain heavier load under low speed. Frequent lubricating should be noticed

NATV series is single row with axial guidance, full complement needle rollers, with gap sealed on both sides.

The kinds of tapered roller bearing and models

Metric single row tapered roller bearing

Inch single row tapered roller bearing

Double row tapered roller bearing

Four row tapered roller bearings

Paired single row tpered roller bearings

Inner diameter 20–150mm

Outer diameter 35–210mm

Details:

1. Less coefficient of friction, High limiting speed, Large size range, Variations of structure.

2. Tapered Roller Bearings are designed such like cup. Cone and rollers have tapered surfaces whose apexes converge at a common point on the bearing axis.

3. Single-row tapered roller bearing is CZPT to carry radial and axial load in 1 directions simultaneously because an axial component of produced when this type of bearings loaded radically, 2 bearings are used together facing 1 another, or 2 or more bearings are matched and used.

Application:

For mounting wherever axial and radial loads are expected

For most parts for torque transmission

Home appliances, electric motors, automotive components

| mm | model | mm | model | N | rpm | |||||||||

| 16 | NATR5 | 14 | NATR5PP | 14 | 5 | 16 | 12 | 11 | 12 | 3050 | 3000 | 2050 | 2400 | 22000 |

| NATV5 | 15 | ANTV5PP | 15 | 5 | 16 | 12 | 11 | 12 | 4500 | 6300 | 3680 | 4300 | 8500 | |

| 19 | NATR6 | 20 | NATR6PP | 20 | 6 | 19 | 12 | 11 | 14 | 3600 | 3650 | 2450 | 2850 | 20000 |

| NATV6 | 21 | NATV6PP | 21 | 6 | 19 | 12 | 11 | 14 | 5700 | 8700 | 4600 | 6750 | 7000 | |

| 24 | NATR8 | 41 | NATR8PP | 41 | 8 | 24 | 15 | 14 | 19 | 4500 | 5400 | 3900 | 4500 | 5000 |

| NATV8 | 42 | ANTV8PP | 42 | 8 | 24 | 15 | 14 | 19 | 8600 | 12000 | 6700 | 9800 | 5500 | |

| 30 | NATR10 | 64 | NATR10PP | 64 | 10 | 30 | 15 | 14 | 23 | 6100 | 7800 | 4500 | 6900 | 11000 |

| NATV10 | 65 | NATV10PP | 65 | 10 | 30 | 15 | 14 | 23 | 10900 | 17000 | 7600 | 11800 | 4500 | |

| 32 | NATR12 | 71 | NATR12PP | 71 | 12 | 32 | 15 | 14 | 25 | 6600 | 9800 | 4660 | 7000 | 9000 |

| NATV12 | 72 | ANTV12PP | 72 | 12 | 32 | 15 | 14 | 25 | 11800 | 19000 | 7800 | 13000 | 3900 | |

| 35 | NATR15 | 103 | NATR15PP | 103 | 15 | 35 | 19 | 18 | 27 | 10500 | 17500 | 7800 | 11500 | 7000 |

| NATV15 | 105 | NATV15PP | 105 | 15 | 35 | 19 | 18 | 27 | 16000 | 32500 | 15710 | 20500 | 3400 | |

| 40 | NATR17 | 144 | NATR17PP | 144 | 17 | 40 | 21 | 20 | 32 | 11800 | 19400 | 9500 | 13500 | 6000 |

| NATV17 | 152 | ANTV17PP | 152 | 17 | 40 | 21 | 20 | 32 | 19600 | 37000 | 1200 | 23000 | 2900 | |

| 47 | NATR20 | 246 | NATR20PP | 246 | 20 | 47 | 25 | 24 | 37 | 17500 | 29800 | 13500 | 22500 | 4900 |

| NATV20 | 254 | NATV20PP | 254 | 20 | 47 | 25 | 24 | 37 | 25800 | 57000 | 19000 | 39500 | 2600 | |

| 52 | NATR25 | 275 | NATR25PP | 275 | 25 | 52 | 25 | 24 | 42 | 19500 | 36500 | 13400 | 23500 | 3600 |

| NATV25 | 285 | ANTV25PP | 285 | 25 | 52 | 25 | 24 | 42 | 29000 | 69600 | 19800 | 40900 | 2100 | |

| 62 | NATR30 | 470 | NATR30PP | 470 | 30 | 62 | 29 | 28 | 51 | 31000 | 57500 | 20900 | 35500 | 2600 |

| NATV30 | 481 | NATV30PP | 481 | 30 | 62 | 29 | 28 | 51 | 45500 | 104000 | 27800 | 60900 | 1700 | |

| 72 | NATR35 | 635 | NATR35PP | 635 | 35 | 72 | 29 | 28 | 58 | 34500 | 67500 | 22500 | 41000 | 2000 |

| NATV35 | 647 | NATV34PP | 647 | 35 | 72 | 29 | 28 | 58 | 50800 | 109500 | 30900 | 70800 | 1400 | |

| 80 | NATR40 | 805 | NATR40PP | 805 | 40 | 80 | 32 | 30 | 66 | 47000 | 91500 | 30900 | 56500 | 1700 |

| NATV40 | 890 | NATV40PP | 890 | 40 | 80 | 32 | 30 | 66 | 64000 | 139000 | 39800 | 87800 | 1300 | |

| 85 | NATR45 | 910 | NATR45PP | 910 | 45 | 85 | 32 | 30 | 72 | 49100 | 98000 | 30600 | 56900 | 1500 |

| 90 | NATV50 | 960 | ANTV50PP | 960 | 50 | 90 | 32 | 30 | 76 | 50500 | 10600 | 30600 | 57500 | 1300 |

| NATR50 | 990 | NATR50PP | 990 | 50 | 90 | 32 | 30 | 76 | 69500 | 187000 | 38700 | 90900 | 1000 | |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Material: | Bearing Steel |

| Load Direction: | Radial Bearing |

| Place of Origin: | Shandong China (Mainland) |

| Transport Package: | According to Per Client′s Requirements |

| Samples: |

US$ 10/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does proper installation and alignment impact the performance and longevity of track bearings?

Proper installation and alignment play a critical role in the performance and longevity of track bearings. Correct installation ensures that the bearings are positioned and secured accurately, while proper alignment ensures that the load is distributed evenly and the bearings operate smoothly. Here’s an explanation of how proper installation and alignment impact the performance and longevity of track bearings:

Installation Impact:

- Load Distribution: Proper installation ensures that the track bearings are aligned and positioned correctly, allowing for even load distribution. When bearings are installed incorrectly, the load may be unevenly distributed, leading to excessive wear on certain parts of the bearings and reduced overall performance.

- Stability and Rigidity: Accurate installation provides stability and rigidity to the track bearings. Properly secured bearings minimize the risk of movement or vibration during operation, which can cause additional stress, premature wear, and potential damage to the bearings and surrounding components.

- Reduction of Misalignment: Correct installation minimizes the chances of misalignment between the track bearings and the track or guide rails. Misalignment can lead to uneven loading, increased friction, and accelerated wear and tear on the bearings. Proper alignment reduces these issues, ensuring smooth and efficient operation.

- Prevention of Contamination: During installation, it is important to take precautions to prevent contamination of the track bearings. Proper handling techniques, cleanliness, and the use of appropriate tools or protective measures help avoid introducing dirt, dust, or debris that can compromise the bearing’s performance and longevity.

Alignment Impact:

- Reduced Friction and Wear: Proper alignment of track bearings helps minimize friction and wear. When bearings are misaligned, excessive forces and irregular motion can occur, leading to increased friction and accelerated wear. Proper alignment ensures that the bearings operate within their intended design parameters, reducing friction and promoting longevity.

- Optimal Load Distribution: Correct alignment ensures that the load is distributed evenly across the track bearings. This prevents excessive stress on specific areas of the bearings, reducing the risk of premature failure and extending their service life. Optimal load distribution also contributes to smoother operation and improved overall performance.

- Minimized Noise and Vibration: Proper alignment helps minimize noise and vibration during operation. Misaligned track bearings can result in irregular motion, leading to unwanted noise and vibration that can affect the performance, comfort, and efficiency of the machinery or equipment. Proper alignment promotes smoother and quieter operation.

- Improved Efficiency: When track bearings are correctly aligned, the machinery or equipment experiences reduced resistance and improved efficiency. Misalignment can result in energy losses, increased power consumption, and decreased overall efficiency. Proper alignment ensures optimal power transfer and minimizes energy wastage.

It is important to follow the manufacturer’s guidelines and recommendations for the specific track bearings being installed. Proper installation techniques, including accurate positioning, secure fastening, and appropriate alignment, contribute to the optimal performance, reliability, and longevity of track bearings in various applications.

How do track bearings enhance the overall efficiency and functionality of linear motion systems?

Track bearings play a crucial role in enhancing the overall efficiency and functionality of linear motion systems. They offer several benefits that contribute to improved performance, increased reliability, and enhanced functionality. Here’s a detailed explanation:

- Reduced Friction: Track bearings are designed to minimize friction between moving components, allowing for smoother and more efficient linear motion. By reducing friction, they help to optimize the efficiency of the system, reducing energy consumption and minimizing wear on the components.

- Precision and Stability: Track bearings provide precise guidance and stability to the linear motion system. They ensure accurate and repeatable motion along the intended path, allowing for precise positioning and control. This is particularly important in applications that require high accuracy, such as CNC machines, robotics, and automated assembly lines.

- Load Distribution: Track bearings distribute the load evenly along their length, allowing for efficient load transfer and reducing the concentration of forces on specific components. This helps to prevent excessive wear, deformation, and premature failure of the system, improving overall reliability and longevity.

- Handling Heavy Loads: Track bearings are specifically designed to handle heavy loads in linear motion systems. They offer high load capacities and robust construction, enabling them to support and move heavy objects with ease. This capability is essential in industries such as material handling, construction, and transportation.

- Smooth and Quiet Operation: Track bearings are engineered to provide smooth and quiet operation, minimizing noise and vibrations in the linear motion system. This is especially important in applications where noise reduction and comfort are critical, such as in medical equipment, office automation, and consumer electronics.

- Versatility and Adaptability: Track bearings come in various designs, sizes, and configurations to accommodate different linear motion system requirements. They can be easily integrated into existing systems or customized to fit specific applications. This versatility allows for greater flexibility and adaptability in designing and implementing linear motion solutions.

- Maintenance and Serviceability: Track bearings are designed for ease of maintenance and serviceability. They often feature removable components, such as seals or shields, that allow for inspection, cleaning, and lubrication. This simplifies maintenance tasks and reduces downtime, contributing to improved overall system efficiency and uptime.

By incorporating track bearings into linear motion systems, industries can benefit from increased efficiency, improved performance, and enhanced functionality. Whether it’s achieving precise positioning, handling heavy loads, reducing friction, or ensuring smooth operation, track bearings play a vital role in optimizing the overall efficiency and functionality of linear motion systems.

Can you describe the load-carrying capacity and load ratings of track bearings?

Track bearings are designed to withstand and carry various types of loads while maintaining smooth and controlled motion along a track or guide rail. The load-carrying capacity and load ratings of track bearings are crucial factors to consider when selecting the appropriate bearing for a specific application. Let’s delve into these concepts:

Load-Carrying Capacity:

The load-carrying capacity of a track bearing refers to its ability to support and distribute the applied loads without excessive deformation or failure. It is influenced by several factors, including the bearing’s design, materials, and operating conditions. The load-carrying capacity is typically specified in terms of static load capacity and dynamic load capacity.

The static load capacity indicates the maximum load that a track bearing can support without permanent deformation. It is determined by the bearing’s internal geometry, material strength, and the contact area between the rolling elements and raceways. Static loads are those that do not cause relative motion between the bearing and the track, such as when the bearing is stationary or subjected to a constant load.

The dynamic load capacity represents the maximum load that a track bearing can handle while still allowing smooth rolling motion. It takes into account the bearing’s ability to handle both radial and axial loads and considers factors such as the bearing’s internal clearance, lubrication, and operating speed. Dynamic loads are those that cause relative motion between the bearing and the track, such as when the bearing is subjected to varying loads or subjected to motion along the track.

Load Ratings:

Load ratings provide standardized values that indicate the maximum allowable loads for track bearings based on industry standards. These load ratings are commonly provided by bearing manufacturers and help users select the appropriate bearing for their specific application requirements. The two primary load ratings used for track bearings are the radial load rating and the axial load rating.

The radial load rating specifies the maximum radial load that a track bearing can withstand while maintaining proper performance and service life. It is expressed as a static load rating and a dynamic load rating. The static radial load rating indicates the maximum radial load that the bearing can support without permanent deformation, while the dynamic radial load rating represents the maximum radial load that the bearing can handle under typical operating conditions.

The axial load rating indicates the maximum axial load that a track bearing can withstand without excessive deformation or failure. It considers the applied axial force in the direction perpendicular to the track or guide rail. The axial load rating is typically provided as a static load rating and a dynamic load rating.

It’s important to note that load ratings are based on specific operating conditions, such as a certain speed, lubrication, and temperature. It is necessary to consider the actual operating conditions and factors such as shock loads, vibrations, and misalignments when applying load ratings to real-world applications.

By understanding the load-carrying capacity and load ratings of track bearings, engineers and designers can make informed decisions to ensure reliable and safe performance of the bearings in their applications.

editor by CX 2024-02-19