Product Description

Hot products

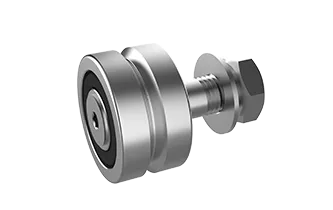

Detail photo

Warehouse

Catalogue

THK Cam Follower Bearing Model

| CF type | CF5UU CF6UU CF8UU CF10UU CF10-1UU CF12 CF12-1UU CF16UU CF18UU CF20UU | |||

| CF20-1UU CF24 CF24-1UU CF30 CF30-1UU CF30-2UU | ||||

| CF-M type | CF5MUU CF6MUU CF8MUU CF10MUU CF10-1MUU CF12MUU CF12-1MUU CF16MUU | |||

| CF20MUU CF20-1MUU CF24MUU CF24-1MUU CF30MUU CF30-1MUU CF30-2MUU | ||||

| CF-UUR type | CF5UUR CF6UUR CF8UUR CF10UUR CF10-1UUR CF12UUR CF12-1UUR CF16UUR | |||

| CF20UUR CF20-1UUR CF24UUR CF24-1UUR CF30UUR CF30-1UUR CF30-2UUR | ||||

| CF5-MUUR type | CF5MUUR CF6MUUR CF8MUUR CF10MUUR CF10-1MUUR CF12MUUR CF12-1MUUR | |||

| CF16MUUR CF20MUUR CF20-1MUUR CF24MUUR CF24-1MUUR CF30MUUR | ||||

| CF30-1MUUR CF30-2MUUR | ||||

| CF-A type | CF5UU-A CF6UU-A CF8UU-A CF10UU-A CF10-1UU-A CF12UU-A CF12-AUU-A CF16UU-A | |||

| CF20UU-A CF20-1UU-A CF24UU-A CF24-1UU-A CF30UU-A CF30-AUU-A CF30-2UU-A | ||||

| CF-MUU-A type | CF5MUU-A CF6MUU-A CF8MUU-A CF10MUU-A CF10-1MUU-A CF12MUU-A | |||

| CF12-1MUU-A CF16MUU-A CF20-1MUU-A CF24MUU-A CF24-1MUU-A CF30MUU-A | ||||

| CF30-1MUU-A CF30-2MUU-A | ||||

| CF-UUR-AB type | CF5UUR-A CF6UUR-A CF8UUR-A CF10UUR-A CF10-1UUR-A CF12UUR-A CF12-1UUR-A | |||

| CF16UUR-A CF18UUR-A CF20-1UUR-A CF24UUR-A CF24-1UUR-A CF30UUR-A | ||||

| CF30-1UUR-A CF30-2UUR-A | ||||

| CF-MUUR-A type | CF5MUUR-A CF6MUUR-A CF8MUUR-A CF10MUUR-A CF10-1MUUR-A CF12MUUR-A | |||

| CF12-1MUUR-A CF16MUUR-A CF18MUUR-A CF20MUUR-A CF20-1MUUR-A | ||||

| CF24MUUR-A CF30MUUR-A CF30-UUR-A CF30-2MUUR-A | ||||

| CF-UU-B type | CF12UU-B CF12-1UU-B CF16UU-B CF18UU-B CF20UU-B CF20-1UU-B CF24UU-B | |||

| CF24-1UU-B CF30UU-B CF30-1UU-B CF30-2UU-B | ||||

| CF-MUUR-B type | CF12MUUR-B CF12-1MUU-B CF16MUUR-B CF18MUUR-B CF20MUUR-B CF20-1MUUR-B CF24MUUR-B CF24-1MUUR-B CF30MUUR-B CF30-1MUUR-B CF30-2MUUR-B | |||

| CFH-UU-A type | CFH6UU-A CFH8UU-A CFH10UU-A CFH10-1UU-A CFH12UU-A CFH12-1UU-A CFH16UU-A CFH18UU-A CFH20UU-A CFH20-1UU-A CFH24UU-A CFH24-1UU-A CFH30UU-A | |||

| CFH30-1UU-A CFH30-2UU-A | ||||

| CFH-UUR-A type | CFH6UUR-A CFH8UUR-A CFH10UUR-A CFH10-1UUR-A CFH12UUR-A CFH12-1UUR-A | |||

| CFH16UUR-A CFH18UUR-A CFH20UUR-A CFH20-1UUR-A CFH24UUR-A CFH24-1UUR-A CFH30UUR-A CFH30-1UUR-A CFH30-2UUR-A | ||||

| CFN-R-A type | CFN5R-A CFN6R-A CFN8R-A CFN10R-A CFN12R-A | |||

| CFT type | CFT6UU CFT8UU CFT10UU CFT12UU CFT10-1UU CFT12-1UU CFT16UU CFT18UU | |||

| CFT20UU CFT20-1UU CFT24UU CFT24-1UU CFT30UU CFT30-1UU CFT30-2UU | ||||

| CFT-UUR type | CFT6UUR CFT8UUR CFT10UUR CFT10-1UUR CFT12UUR CFT12-1UUR CFT16UUR | |||

| CFT18UUR CFT20UUR CFT20-1UUR CFT24UUR CFT24-1UUR CFT30UUR CFT30-1UUR | ||||

| CFT30-2UUR | ||||

| CFH-MUU-A type | CFH6MUU-A CFH6MUUR-A CFH6UU-A CFH6UUR-A CFH8MUU-A CFH8MUUR-A | |||

| CFH8UU-A CFH8UUR-A CFH10-1MUU-A CFH10-1MUUR-A CFH10-1UU-A CFH10-1UUR-A CFH10MUU-A CFH10MUUR-A CFH10UU-A CFH10UUR-A CFH12-1MUU-A | ||||

| CFH12-1MUUR-A CFH12-1UU-A CFH12-1UUR-A CFH12MUU-A CFH12MUUR-A | ||||

| CFH12UU-A CFH12UUR-A CFH16MUU-A CFH16MUUR-A CFH16UU-A CFH16UUR-A | ||||

| CFH18MUU-A CFH18MUUR-A CFH18UU-A CFH18UUR-A CFH20-1UU-A CFH20-1UUR-A CFH20MUU-A CFH20MUUR-A CFH20UU-A CFH20UUR-A CFH24-1UU-A CFH24-1UUR-A | ||||

| CFH24UU-A CFH24UUR-A CFH30-1UU-A CFH30-1UUR-A CFH30-2UU-A CFH30-2UUR-A | ||||

| CFH30UU-A CFH30UUR-A | ||||

| CFH-A type | CFH6-A | CFH6M-A | CFH6MR-A | CFH6R-A | CFH8-A | CFH8M-A | CFH8MR-A | CFH8R-A| | |||

| CFH10-1-A | CFH10-1M-A | CFH10-1MR-A | CFH10-1R-A| CFH10-A | CFH10M-A | | ||||

| CFH10MR-A | CFH10R-A | CFH12-1-A | CFH12-1M-A | CFH12-1MR-A | CFH12-1R-A | | ||||

| CFH12-A | CFH12M-A | CFH12MR-A |CFH12R-A | CFH16-A | CFH16M-A | CFH16MR-A | | ||||

| CFH16R-A | CFH18-A | CFH18M-A | CFH18MR-A | CFH18R-A | CFH20-1-A | CFH20-1R-A| | ||||

| CFH20-A | CFH20M-A | CFH20MR-A | CFH20R-A | CFH24-1-A | CFH24-1R-A | CFH24-A | | ||||

| CFH24R-A | CFH30-1-A | CFH30-1R-A | CFH30-2-A |CFH30-2R-A | CFH30-A | CFH30R-A | ||||

| CF-M-A type | CF3M-A | CF4M-A | CF5M-A | CF6M-A | CF8M-A | CF10-1M-A | CF10M-A | CF12-1M-A | | |||

| CF12M-A | CF16M-A | CF18M-A | CF20-1M-A | CF20M-A |CF24-1M-A | CF24M-A | | ||||

| CF30-1M-A | CF30-2M-A | CF30M-A | ||||

| CF-MUU-A type | CF3MUU-A | CF4MUU-A | CF5MUU-A | CF6MUU-A | CF8MUU-A | CF10-1MUU-A | | |||

| CF10MUU-A | CF12-1MUU-A | CF12MUU-A | CF16MUU-A | CF18MUU-A |CF20-1MUU-A | | ||||

| CF20MUU-A | CF24-1MUU-A | CF24MUU-A | CF30-1MUU-A | CF30-2MUU-A | CF30MUU-A | ||||

Workshop

Certifications

Cooperated brand

FAQ

Q: How do you pack the goods?

- Total less than 25 KG : Each in white box + 19*18*9cm box + 29*28*19CM carton box

- Total Weight over 100KG : Carton box + Wooden Box / Wooden Pallet

Q: Can i get the samples from you?

A: It is highly encouraged to ask for the samples for quality check.

Q: Can you promise to deliver the goods in time?

- Small items: In stock.

- Medium Items: 10-15 Days

- Big items: 20-25 Days

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Cage: | With Cage |

|---|---|

| Material: | Bearing Steel, Stainess Steel |

| Quality: | Low Noise |

| Life: | Long Life |

| Price: | Factory Price |

| Factory: | Made by Japan THK Company |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

What are the considerations for selecting the right track bearings for a particular application?

Selecting the right track bearings for a particular application requires careful consideration of various factors to ensure optimal performance, reliability, and longevity. Here are the key considerations to keep in mind:

- Load Requirements: Assess the expected load conditions in the application. Consider both the static and dynamic loads that the track bearings will need to support. Determine the maximum load capacity required to ensure that the selected bearings can handle the anticipated loads without premature failure or excessive wear.

- Speed and Acceleration: Evaluate the speed and acceleration requirements of the application. Higher speeds and rapid accelerations can impose additional stresses on the track bearings. Choose bearings with suitable speed and acceleration ratings to ensure they can operate effectively within the desired range without compromising performance or causing premature wear.

- Environmental Factors: Consider the operating environment of the application. Evaluate factors such as temperature extremes, moisture, dust, chemicals, and potential exposure to corrosive substances. Select track bearings that are designed to withstand the specific environmental conditions to ensure optimal performance and longevity.

- Track and Rail Compatibility: Assess the compatibility of the track bearings with the existing track or rail system. Consider factors such as track geometry, dimensional requirements, and mounting options. Ensure that the selected bearings are suitable for the specific track or rail design to facilitate proper installation, alignment, and smooth operation.

- Maintenance and Lubrication: Evaluate the maintenance and lubrication requirements of the track bearings. Consider factors such as the need for regular maintenance, lubrication intervals, and the availability of suitable lubricants. Choose bearings that align with the desired maintenance practices and provide appropriate lubrication options based on the application’s operational demands.

- Expected Lifespan and Reliability: Determine the desired lifespan and reliability expectations for the track bearings. Consider factors such as the projected operating hours, duty cycles, and the criticality of the application. Select bearings from reputable manufacturers known for producing high-quality, reliable products that align with the expected lifespan and reliability requirements.

- Cost Considerations: Evaluate the cost-effectiveness of the track bearings. Consider the initial purchase cost as well as the long-term costs associated with maintenance, replacement, and potential downtime. Strive for a balance between the upfront investment and the overall value provided by the bearings in terms of performance, reliability, and longevity.

It is essential to consult with bearing manufacturers or industry experts who can provide guidance and recommendations based on the specific application requirements. By considering these factors and seeking expert advice, you can select the right track bearings that best meet the needs of your particular application.

How do track bearings enhance the overall efficiency and functionality of linear motion systems?

Track bearings play a crucial role in enhancing the overall efficiency and functionality of linear motion systems. They offer several benefits that contribute to improved performance, increased reliability, and enhanced functionality. Here’s a detailed explanation:

- Reduced Friction: Track bearings are designed to minimize friction between moving components, allowing for smoother and more efficient linear motion. By reducing friction, they help to optimize the efficiency of the system, reducing energy consumption and minimizing wear on the components.

- Precision and Stability: Track bearings provide precise guidance and stability to the linear motion system. They ensure accurate and repeatable motion along the intended path, allowing for precise positioning and control. This is particularly important in applications that require high accuracy, such as CNC machines, robotics, and automated assembly lines.

- Load Distribution: Track bearings distribute the load evenly along their length, allowing for efficient load transfer and reducing the concentration of forces on specific components. This helps to prevent excessive wear, deformation, and premature failure of the system, improving overall reliability and longevity.

- Handling Heavy Loads: Track bearings are specifically designed to handle heavy loads in linear motion systems. They offer high load capacities and robust construction, enabling them to support and move heavy objects with ease. This capability is essential in industries such as material handling, construction, and transportation.

- Smooth and Quiet Operation: Track bearings are engineered to provide smooth and quiet operation, minimizing noise and vibrations in the linear motion system. This is especially important in applications where noise reduction and comfort are critical, such as in medical equipment, office automation, and consumer electronics.

- Versatility and Adaptability: Track bearings come in various designs, sizes, and configurations to accommodate different linear motion system requirements. They can be easily integrated into existing systems or customized to fit specific applications. This versatility allows for greater flexibility and adaptability in designing and implementing linear motion solutions.

- Maintenance and Serviceability: Track bearings are designed for ease of maintenance and serviceability. They often feature removable components, such as seals or shields, that allow for inspection, cleaning, and lubrication. This simplifies maintenance tasks and reduces downtime, contributing to improved overall system efficiency and uptime.

By incorporating track bearings into linear motion systems, industries can benefit from increased efficiency, improved performance, and enhanced functionality. Whether it’s achieving precise positioning, handling heavy loads, reducing friction, or ensuring smooth operation, track bearings play a vital role in optimizing the overall efficiency and functionality of linear motion systems.

What are track bearings, and how are they used in various applications?

Track bearings, also known as track rollers or track follower bearings, are specialized rolling bearings designed to operate in track-based systems. They are used in various applications that require guided linear or rotational motion. Let’s explore in detail the characteristics of track bearings and their common applications:

- Design and Construction: Track bearings typically consist of an outer ring, an inner ring, a set of rolling elements (such as rollers or needles), and a cage that holds the rolling elements together. The outer ring features a track or guide surface, while the inner ring is mounted on a shaft or stud. The rolling elements facilitate smooth rolling motion along the track, allowing for linear or rotational movement.

- Guided Motion: Track bearings are primarily used to provide guided motion in applications where components need to move along a defined path or track. The outer ring’s track surface interfaces with the track or guide rail, ensuring precise and controlled motion. This guided motion is crucial in various applications such as material handling systems, conveyors, cam mechanisms, and automated machinery.

- Load Support: Track bearings are designed to support and distribute loads, both radial and axial, in track-based systems. They can handle substantial loads while maintaining smooth motion and minimizing friction. The load-carrying capacity of track bearings makes them suitable for applications involving heavy loads, such as construction equipment, agricultural machinery, and industrial automation systems.

- Multiple Types: Track bearings come in various types to suit different application requirements. Some common types include yoke type track rollers, stud type track rollers, and cam followers. Yoke type track rollers have thick outer rings and can withstand high radial loads. Stud type track rollers have a stud instead of an inner ring and are suitable for applications with limited space. Cam followers have a stud with a built-in roller and are commonly used in cam-driven systems.

- Sealing and Contamination Protection: In many applications, track bearings are exposed to harsh environments and contaminants. To ensure reliable operation, track bearings often incorporate sealing arrangements or protective coatings. These features help prevent the ingress of dust, dirt, moisture, or other contaminants, prolonging the bearing’s service life and reducing the risk of premature failure.

- Various Applications: Track bearings find applications in a wide range of industries and systems. Some common applications include:

- Material Handling Systems: Track bearings are used in conveyors, roller tracks, and overhead cranes to facilitate smooth and guided movement of materials.

- Automated Machinery: Track bearings are employed in automated machines and robotic systems for precise motion control and positioning.

- Cam Mechanisms: Track bearings are utilized in cam-driven systems, where they follow the profile of the cam and translate the rotary motion into linear or oscillating motion.

- Construction Equipment: Track bearings are found in construction machinery, such as excavators, bulldozers, and compactors, to support the tracks or guide wheels.

- Agricultural Machinery: Track bearings are used in agricultural equipment, including tractors, combines, and harvesters, to support the tracks or guide wheels and provide reliable movement.

- Printing and Packaging Machinery: Track bearings are employed in printing presses, packaging machines, and labeling systems to ensure precise and guided movement of the printing heads, packaging materials, or labels.

In summary, track bearings are specialized rolling bearings designed for guided linear or rotational motion along a track or guide rail. They provide precise motion control, support substantial loads, and find applications in various industries such as material handling, automation, construction, agriculture, printing, and packaging. With their ability to facilitate guided motion and handle significant loads, track bearings contribute to the smooth and reliable operation of track-based systems in a wide range of applications.

editor by CX 2024-01-11